Innovation Begins with the Customer – ELSX™ Rotary Joint

Customer Insights

At Kadant Johnson, innovation begins with the customer. A robust understanding of customer insights is conducted before any design work begins. In the case of the ELSX rotary joint, two key user insights were identified. The first is that producers are demanding greater uptime. The second is that producers are increasing operating speed and pressure.

Increased uptime is not only driven by the need to maintain production, but also the reduction in maintenance personnel. As maintenance employees retire and maintenance groups shrink, producers simply don’t have the knowledge or staffing to maintain rotary joints.

Increased uptime is not only driven by the need to maintain production, but also the reduction in maintenance personnel. As maintenance employees retire and maintenance groups shrink, producers simply don’t have the knowledge or staffing to maintain rotary joints.

Increasing operating conditions are driven by the producers’ desire to increase profits as well as be more responsive to their ever-demanding customers. To increase run rates, machine speeds are increasing, and to provide the required heat transfer at higher speeds, operating pressures are also increasing. This higher combined pressure and velocity (PV) wear out rotary joint sealing components much quicker; analogous to sandpaper rubbed harder and faster on a surface.

Design Development

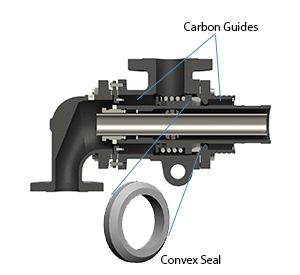

These user insights were at the center of the ELSX rotary joint development. Kadant Johnson engineers first reduced the pressure and tangential speed on the seal ring with a convex seal design. The result was up to a 20% increase in PV capability in steam applications. Then, they increased the wearable ring seal material by up to 15% for extended wear life. To further improve uptime, the wear surface and separation of carbon guides were extended for more stability.

These user insights were at the center of the ELSX rotary joint development. Kadant Johnson engineers first reduced the pressure and tangential speed on the seal ring with a convex seal design. The result was up to a 20% increase in PV capability in steam applications. Then, they increased the wearable ring seal material by up to 15% for extended wear life. To further improve uptime, the wear surface and separation of carbon guides were extended for more stability.

Kadant Johnson’s product development group designed the ELSX rotary joint for more uptime and more demanding operating conditions by keeping user needs and insights at the center of its development.