How Multi-Passage Rotary Unions Work

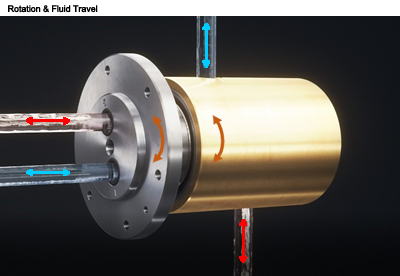

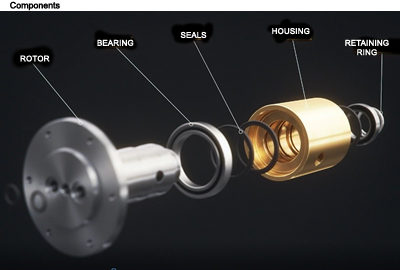

Multi-passage rotary unions transfer media into and out of rotating equipment without leaking or loss of pressure. Either end of the rotary union can rotate, and fluid can travel in any direction. The components of a basic multi-passage rotary union are a rotor, bearings, seals, housing, and retaining ring.

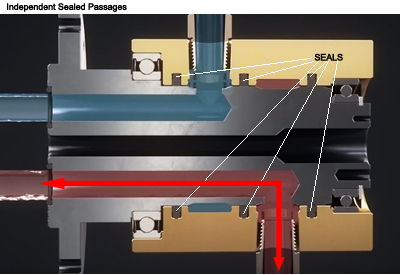

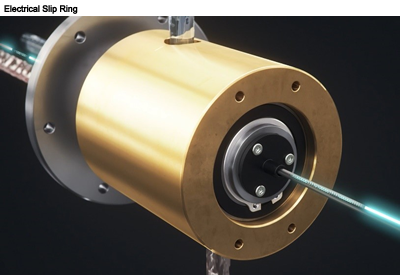

The components create independently sealed passages for media flow. Media separation is maintained using seals between the housing and rotor. When electrical power or data transfer must be combined with media transfer, multi-passage rotary unions integrate directly with electrical slip rings. Both electrical and fluid media are transferred simultaneously.

Multi-passage rotary unions transfer media into and out of rotating equipment without leaking or loss of pressure. Either end of the rotary union can rotate, and fluid can travel in any direction. The components of a basic multi-passage rotary union are a rotor, bearings, seals, housing, and retaining ring.

Multi-passage rotary unions are used in applications and industries where water, steam, or other media transfer is needed. The number of passages, types of media, and flow rates are only limited by the size of the rotary union and separate channels allow media to flow in any combination of directions. Choosing the right materials, sealing technology, and engineered design for each application is the key to reliable, leak-free performance.

Watch this video to learn more about multi-passage rotary unions.