Pump stopped, but water keeps coming. The Vacuum Breaker Solution.

A plant is pumping 600 gallons per minute (GPM) of chill water through an 8” pipe into an open tank. Pipefitters plan to add a tee just above the open tank.

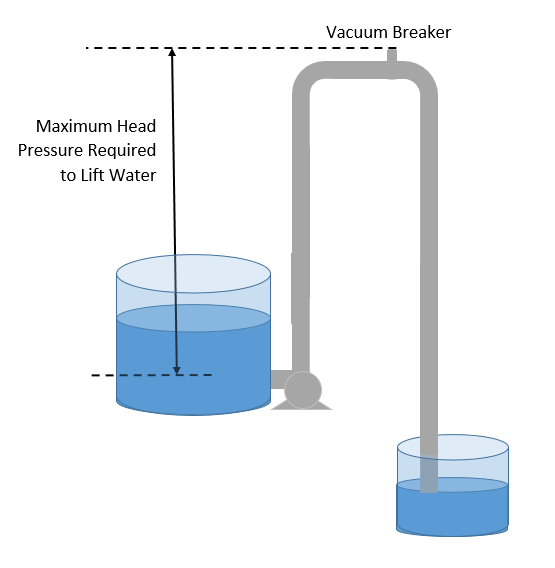

The piping installation creates the perfect condition for siphoning, i.e., when the pump is shut off, the water continues to flow. The pump pressure is gone, and in its place, negative pressure or a vacuum creates a siphoning effect and the water continues to fill the tank. Without intervention, the flow will continue until the water level drops below the supply pipe’s inlet. To stop the ongoing flow vacuum, install a vacuum breaker at the highest point in the piping.

How does a Vacuum Breaker work?

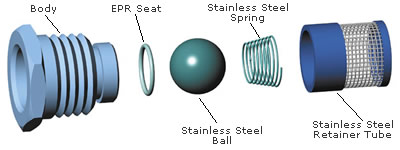

Vacuum breakers are made up of five parts including the body, O-ring, ball, spring, and retainer tube. When installed, the spring holds the ball against the O-ring. When there is sufficient negative pressure or vacuum to compress the spring and move the ball off the O-ring seat, the valve opens to atmospheric pressure and pulls in air. Vacuum breakers come in different sizes; each one has a different open vacuum requirement and passes a set volume air controlled by the vacuum breaker’s orifice size. Also, a vacuum breaker beyond stopping a siphoning effect can also prevent the collapse of pipes and tanks, and help drain pipelines that vacuum can slow or stop.

Which vacuum breaker size do I use?

Which vacuum breaker size do I use?

For a vacuum breaker to dissipate vacuum, selecting the correct vacuum breaker size is critical. Two factors influence sizing: 1) the flow volume of the water, and 2) the head pressure required to lift the water. In our chill water example, the vacuum breaker needs to have the capacity to flow as much air volume into the piping as the chilled water flow at a head pressure that is less than it takes to lift the water. To determine this volume, convert the chilled water flow rate of 600 GPM into standard cubic feet per minute (scfm). As a vacuum breaker operates nears atmospheric pressure, this can be said to in “standard” cubic feet per minute (scfm). Divide 600 GPM by 7.5 gallons per cubic foot and the result is 80 scfm.

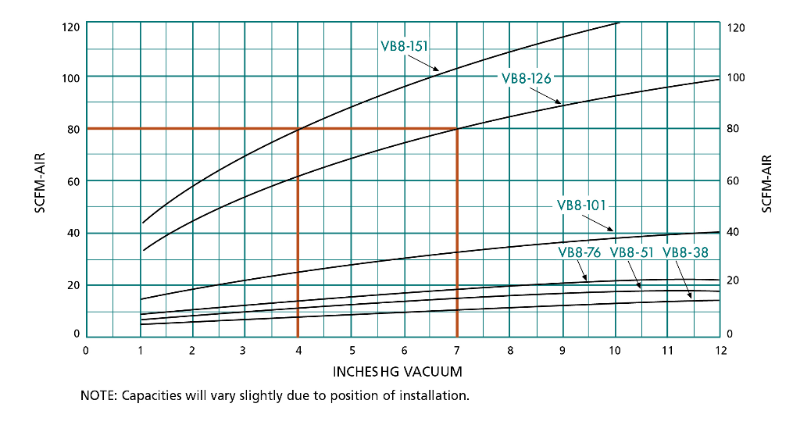

The vacuum breaker needs to move 80 scfm air to break the vacuum. The following chart shows two vacuum breaker sizes that will pass 80 scfm, the 1½” (VB8-151) vacuum breaker and the 1¼” (VB8-126) vacuum breaker. The chart also shows, to move 80 scfm of air through the 1½” valve the vacuum requires four inches of Mercury (inHg) or 4.5 feet of water column, and to move 80 scfm of air through the 1¼” vacuum breakers requires seven inHg (8 feet of water column).

It is important to pass the air at a lower head pressure than the pressure it will take to lift the water to the highest point. Otherwise, you will not generate enough vacuum to bring in enough air through the vacuum breaker to stop the siphon drainage.

To find the maximum head, measure the distance between the pipe supply inlet and the high point where the vacuum breaker is located. Convert from feet to inches of Mercury (inHg) by multiplying by 0.88 inHg/ft. Examples, if the water is lifted:

- 8 feet (7 inHg), the 1-1/4” vacuum breaker, will work

- 4 feet (4 inHg), you need the larger 1-1/2” vacuum breaker

- 2 feet (1.77 inHg), you will need a pair of 1-1/4” vacuum breakers.

- 0 feet, you have gravity drainage, not siphon drainage, and a vacuum breaker will not stop the flow.

Note that this method of sizing a vacuum breaker for siphon drainage, is conservative because it is very likely that the siphon drainage will break before you reach the full replacement air flow. It is not easy to calculate the exact percentage of the water flow that needs to be replaced by the air flow because it will vary based on system layout and flow conditions. We do know 100% replacement with air will always break the siphon drainage.

Vacuum Breaker Installation Tips

Install the vacuum breaker at a high point in the piping above the open tank. Because this may be in a remote location, we recommend using a vacuum breaker with a female threaded outlet versus the version that has a plain threaded outlet. To the threaded outlet vacuum breaker, add a small pipe or hose line, with a gooseneck bend, and direct the line away from pedestrian traffic and equipment that doesn’t mix well with water. Because the vacuum breaker ball seats on an O-ring seal, someday this O-ring will no longer seal properly, and the vacuum breaker will leak. Locate this line in a place operators can monitor, observe a leak, and know when to replace the vacuum breaker. This line also helps keep dirt and debris out of the vacuum breaker that can lead to a leak when particles get trapped between the ball and the O-ring seal.

The other end of the vacuum breaker body has an outside diameter male thread used to mount the valve in your piping. We recommend using a standpipe with a coupling, to prevent damage to the vacuum breaker if it was installed in the direct water flow.

Erich Bernhardt also contributed to this post.