Doctoring Tips from the Experts

I had the opportunity to sit down with Jon Olszak and Mike Six, regional applications managers for doctoring, to discuss doctor blade tips and applications for the pulp and paper industry. Jon and Mike have over 35 years of doctoring and rolling cleaning experience.

V: What is the number one tip you could give someone when choosing a doctor blade for a paper machine?

J: There are many different doctoring applications on a paper machine consisting of various roll materials and blade materials. Contact an expert for advice.

M: Consult with a doctor blade expert. There are a variety of doctor blade choices and the wrong blade can damage a roll or allow a sheet to pass.

V: How do you determine which blade material is most appropriate?

J: Normally blade material is selected based on the roll material and the application (is the roll material metal, rubber, etc.). Avoid putting a sharp metal blade on a soft rubber cover and don’t run similar materials against each other as they would have a tendency to gall. Blade life is a major factor in selecting a blade material. The application is also important including the blade function/requirements, roll temperature, and other environmental factors. For example, I would not use a blade rated for 200° in a 400° environment and would not use a poly blade to try and remove coating build up off a dryer can.

M: To determine the best blade material for the application you must consider the type of doctor system to be used, the application on the machine, the roll material/hardness, grade of paper, and the machine speed.

V: What are the main priorities when choosing a doctor blade holder?

J: The application is the main priority. With an understanding of the application, we can match the best holder. Key application conditions include the PLI requirement, blade thickness requirement, self-conforming or manual profile, temperature requirement, rigid or flexible design, and corrosive environments. There are holders designed to perform under certain conditions and understanding the holder’s capabilities and the requirements of the application are critical when selecting the proper doctor blade holder.

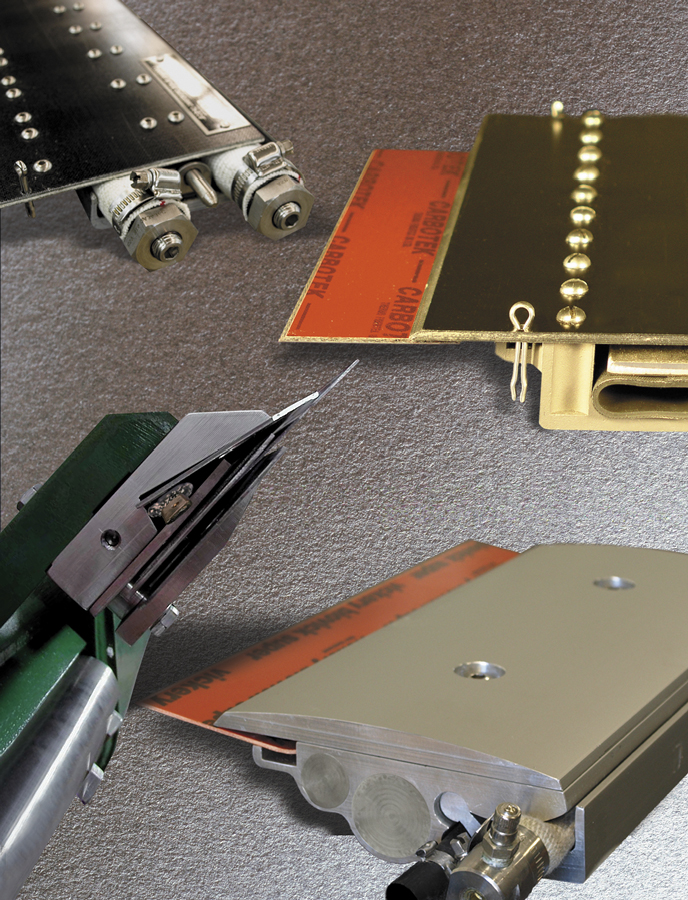

M: A doctor blade holder needs to match the application. In a dewatering application, consider a blade holder in the patented AirSet™ doctor blade holder group to maximize water removal rather versus an ordinary DST type holder. For sheet shedding applications a heavy duty blade holder with stainless top plate like the StaClean™ or Uniflex™ doctor blade holders should be considered. In a felt or wire roll application, consider a DST type blade holder with composite top plate like the UniSet™ doctor blade holder to maximize conformability.

In addition, consider how the doctor blade holder will be loaded. If air cylinders are preferred for heavy duty sheet shedding/roll cleaning, the UniFlex™ or stainless steel AccuTek™ doctor blade holder works well. If a turnbuckle positioned DST type holder is preferred consider using air over fluid loading for critical sheet shedding positions. For light duty applications a pressure rig loaded composite AccuTek doctor blade holder or a bracket-to-bracket doctor with a UniSet doctor blade holder on stationary rolls are good options.

In addition, consider how the doctor blade holder will be loaded. If air cylinders are preferred for heavy duty sheet shedding/roll cleaning, the UniFlex™ or stainless steel AccuTek™ doctor blade holder works well. If a turnbuckle positioned DST type holder is preferred consider using air over fluid loading for critical sheet shedding positions. For light duty applications a pressure rig loaded composite AccuTek doctor blade holder or a bracket-to-bracket doctor with a UniSet doctor blade holder on stationary rolls are good options.

And finally, avoid fingered DST blade holders (standard DST or DST-R) because they cannot be sealed from debris entering the holder cavity. Most non-Kadant DST type blade holders fall into this category. Many Kadant doctor blade holders are either slide out removable standard or can be used with a unitrak option. This is unique to Kadant and can make maintenance much easier.

V: What are common questions/problems you experience while dealing with doctor blades in paper mills and what have been your solutions?

J: Maintaining proper sheet release in the press section is a common problem in the pulp and paper industry. There have been a number of advances with roll covers and doctoring equipment to help improve and maintain sheet release. Using the proper blade material and equipment is critical when trying to optimize sheet release. If set-up properly, doctoring and showering equipment can help maintain roll release properties for an extended period of time.

M: A common issue is poor doctoring performance due to poor doctor and/or doctor blade holder hygiene and maintenance. Showing the user the value of using Kadant service, technical expertise, and blade materials that can increase machine runnability. Kadant has the ability to provide local service and technical expertise throughout the country and around the globe.

V: What are some unique problems you have found in paper mills and how were they solved?

J: Paper machines with a center press doctor may experience the sheet hitting the primary doctor blade and exiting at an angle instead of dropping straight down into the press pit. There is not always a single, straight forward answer to solve this problem. The solution usually involves addressing multiple areas including the doctor equipment, doctor set-up, blade material, blade design, blade loading pressure, showering, shower water temperature, as well as, roll cover condition including RA and release properties.

When this problem occurs I recommend starting with the basics. First, make sure the doctoring equipment is adequate and in good operating condition. Second, check the basic equipment alignment and set-up. If the basics check-out properly, move to blade material and geometry. Proper shower set-up should also be reviewed by confirming proper shower locations, water pressure, volume, coverage, and temperature. Evaluate the condition of the roll cover. Proper roll surface conditions are critical, so roll RA and roll surface contamination should be reviewed. Release aides and chemical cleaning agents are often used in the shower water either continuously or periodically as needed to address this.

M: Actually, the most unique problem I helped solve in a paper mill was with Kadant’s line of wet end tailcutters. A customer wanted to cut on the felt just before the pickup roll. The customer also wanted the ability to remove the cutter from the machine without using the overhead crane or removing the felt or wire. We designed a unit that was cantilevered from the TS rather than the more DS which is typical. The unit was designed so that it can be removed on a sliding rail positioned on the machine floor. The system has performed well and solved the customer’s unique problem.