Exploring the New VeriFlex™ Oscillation System with Dave Leeman

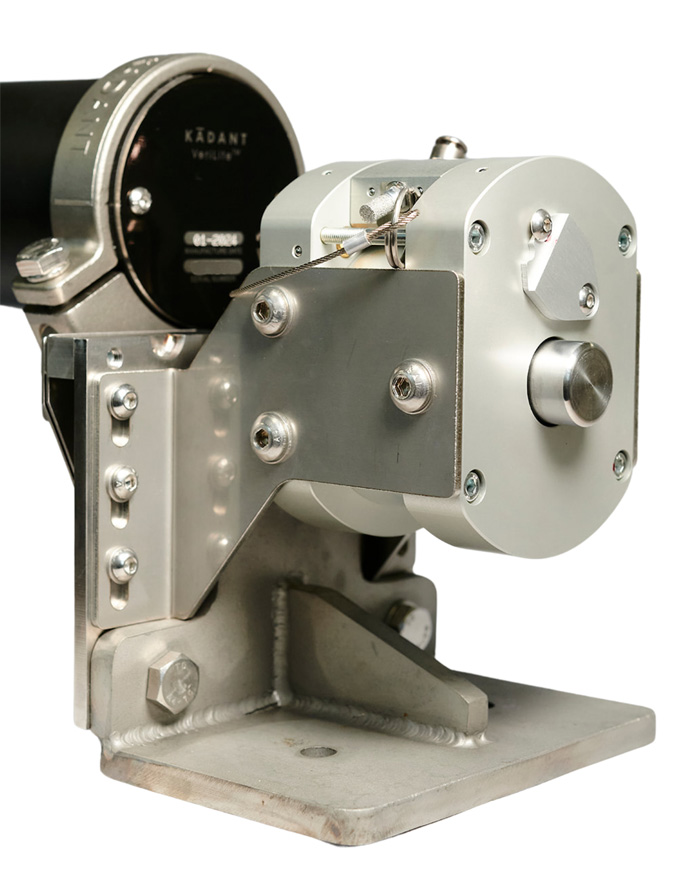

The new VeriFlex oscillation system, designed specifically for the VeriLite™ roll cleaner assembly, employs the Varimatic™ 500 oscillator to enhance the effectiveness of roll cleaning. I spoke with Dave Leeman, Sr. Product Development Engineer and a 38-year veteran of Kadant Solutions, to delve deeper into how the VeriFlex oscillation system elevates the customer experience.

The new VeriFlex oscillation system, designed specifically for the VeriLite™ roll cleaner assembly, employs the Varimatic™ 500 oscillator to enhance the effectiveness of roll cleaning. I spoke with Dave Leeman, Sr. Product Development Engineer and a 38-year veteran of Kadant Solutions, to delve deeper into how the VeriFlex oscillation system elevates the customer experience.

V: Dave, can you explain what the VeriFlex oscillation system is?

D: Absolutely. The VeriFlex oscillation system is a breakthrough in roll cleaning technology. It integrates innovative flex elements that significantly reduce wear and tear, creating a durable, low-maintenance solution. This system doesn’t require any external controls and operates solely on a compressed air supply, which simplifies its installation and maintenance.

V: How does the oscillation system's design improve the performance of the cleaning blade?

D: The VeriFlex oscillation system is designed with a unique bearing mechanism that eliminates the need for frequently replaced parts found in traditional bearings. It incorporates spring elements that can flex back and forth continuously without suffering fatigue failure. With no other wear parts, our system ensures long-lasting performance and durability, enhancing the effectiveness of the roll cleaning process.

V: What has been your role in the development of this technology?

D: My main role has been building and proving that the system works. It's been a team effort from the start, but I focused particularly on the practical application and testing phases, ensuring the system performed as intended under real-world conditions.

V: Can you tell us more about the early stages of the VeriFlex oscillation system's development?

D: The concept originated nearly 20 years ago when we were addressing a challenge within the paper industry. Although that specific challenge was eventually solved differently, it laid the groundwork for what would eventually become the VeriFlex oscillation system. The idea was revisited as we recognized a growing need in various process industries—like metals, food, and nonwovens—for reliable small movement and load oscillation solutions.

V: What was the approach to the design and testing of the VeriFlex oscillation system?

D: Once we pinpointed the need for this system, we dove into the finite element analysis (FEA) to design elements that could withstand the need for 24/7 operation without succumbing to wear and fatigue. The goal was to create a system that, like some metals that can flex indefinitely without breaking, wouldn't fail under continuous use. We conducted extensive testing and design iterations, leveraging a collaborative team effort to refine and perfect the design.

V: What challenges led to developing the VeriFlex oscillation system?

D: We had a previous oscillation system that, while functional, was prohibitively expensive and overly complex. Its components were not only difficult to access but also costly to replace. With the VeriFlex oscillation system, we’ve streamlined the design to make it universally compatible across the 2.5” and 3.5” versions of the VeriLite roll cleaner assembly. This system is more accessible, simpler to maintain, and significantly less expensive, addressing the main pain points we observed in the field.

V: Can you elaborate on the specific problems the VeriFlex oscillation system is solving?

D: Of course. The primary benefit of the VeriFlex oscillation system is its ability to maintain continuous lateral movement of the roll cleaning blade across the roll without relying on traditional bearing slide surfaces, which can wear over time. This action is crucial for removing contaminants effectively and preventing debris from scoring the roll’s surface, which can be extremely costly and time-consuming to repair. The simpler design also means that even customers who previously opted out of oscillation systems due to complexity might consider this efficient alternative.

V: What should customers know about the maintenance and operation of the system?

D: The feedback we've received highlighted that the complexity of the previous system often made it daunting. The VeriFlex oscillation system, in contrast, is straightforward. It’s designed to be user-friendly, requiring minimal training for operation and maintenance. Its compact and open design ensures that parts are easily accessible, reducing the typical hassle associated with upkeep.

Let's Connect

Connect with Kadant Solutions Division on LinkedIn to learn more about our employees, products, and services.