Kadant Flow Control Italy Opens a New Office to Meet Market Needs

Kadant Flow Control Italy recently opened a new office dedicated to the paper industry. The office, located in Capannori, is in the heart of Tuscany and in the Italian hub.

This decision was made by the need to have a more grounded and operative presence in the Italian territory, especially in the Lucca district, a strategic area for paper and tissue manufacturers.

The goal of having an office and a dedicated team in this area is to offer a more extensive service for Fluid Handling and DCF (Doctoring, Cleaning, and Filtration) solutions,

Know-how and expertise

The team that will work out of this new location is led by Fabio Miccoli, technical & sales manager, and skilled professional with more than 26 years of "hands-on" experience in paper mills; and Raffaele Lupinetti, the service engineer, and responsible for installation, audit, and maintenance on Kadant flow control systems.

Benefits for customers

The new team brings extensive knowledge related to the paper production process, from raw material to finished product, which allows them to provide a real benefit to customers in providing support and prompt solutions for the specific needs of the target market. Specifically, the unique competitive advantages of this new office and team include:

- Responsiveness: Being only a few kilometers away from the largest European hub dedicated to paper production, the team can quickly intervene to provide in-person assistance for every need

- Understanding of the Work-Process: the team deeply understands the papermaking process, this allows them to provide highly qualified consulting and technical support services

- Innovation and Quality: Kadant's dedicated DCF solutions such as scraping, cleaning, washing, and filtration systems are designed to improve operational efficiency, reduce water and energy consumption, and ensure high-quality end products

Solutions with a focus on efficiency, quality, and return on investment

Kadant has always focused on solutions that promote environmental sustainability, reducing environmental impact, resource consumption, and improving the energy efficiency of machines.

The M-clean™ cleaning system , for instance, using a high-pressure and a dynamic vacuum system, provides significant savings in the use of fresh water and also natural gas normally used in the process for its heating. The special feature of the system allows not only to effectively remove contaminants, but also to improve fabric cleanliness, to reduce circular holes in paper sheets, and to achieve significant thermal savings compared to traditional needle jets and traditional sprayers.

, for instance, using a high-pressure and a dynamic vacuum system, provides significant savings in the use of fresh water and also natural gas normally used in the process for its heating. The special feature of the system allows not only to effectively remove contaminants, but also to improve fabric cleanliness, to reduce circular holes in paper sheets, and to achieve significant thermal savings compared to traditional needle jets and traditional sprayers.

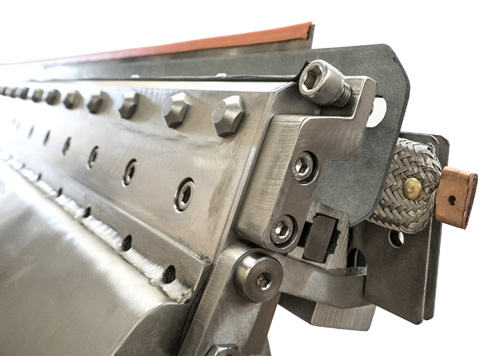

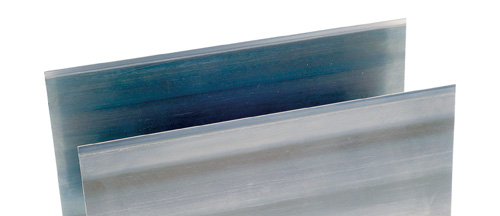

Conformatic™ AL and CeraEdge™ Blades

Kadant is focused on providing not just products, but complete solutions to meet specific needs and solve practical problems. An example of this is the new generation of Conformatic™ blade holders, rigid systems designed to prevent external vibration from being transmitted from the blade holder to the Yankee, eliminating the "chatter mark" effect that is considered an industry benchmark for tissue production. Kadant is always by the side of tissue customers; today, there is an increasing emphasis on product quality, which must possess specific features such as extreme softness, consistency, and strength. These requirements lead to products such as ceramic CeraEdge™ blades that enable superior quality characteristics.

A benchmark for the paper industry

The ultimate goal, which includes the new office, is to create a "hub of technical excellence" for Kadant and its solutions, with a special focus on doctoring and cleaning for the paper industry. This initiative, which involves many professionals dedicated to the world of paper production, does not focus on the commercial and sales process; instead, it focuses on the possibility of providing 360 degree of technical assistance and consulting activity that is a landmark for the Italian market, promoting long-term cooperation projects with customers.