Water and Money Savings: Full Width Shower versus Traversing Shower for Tissue Mills

Most tissue mills focus their fabric cleaning and conditioning efforts on improving cleaning efficiency and effectiveness by focusing on:

- Removing stickies more effectively

- Reducing water consumption

- Reducing energy costs

- Minimizing or eliminating mist generated by high-pressure spray nozzles

- Transporting captured contaminants and oil away from the machine and water loop

- Stopping or minimizing passivation usage

As an example, consider a U.S. tissue mill that was looking for new methods to improve its hygiene and fabric cleaning processes to achieve better operating performance. Several alternatives were discussed, including options to use a full-width shower and a traversing shower system. Based on the trial results of the mill’s fabric sample tested on Kadant’s pilot machine in Sweden, the benefits of the M-clean cleaning system were deemed the best alternative when it came to cost-effective fabric cleaning. The mill also wanted to know if a traversing shower could clean the fabric at the same frequency of a full-width shower. The answer is, yes.

Full-width Shower

Full-width Shower

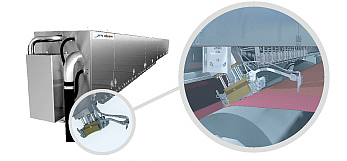

Traversing Shower

Traversing Shower

Despite the improved cleaning achieved by the M-clean™ tissue fabric cleaning system, water consumption and cost savings ended up being the main focus. This particular machine uses municipal fresh water in the showers at a cost of $6 per 1,000 gallons. Two fabrics where considered for this analysis: an outer forming fabric and a TAD fabric.

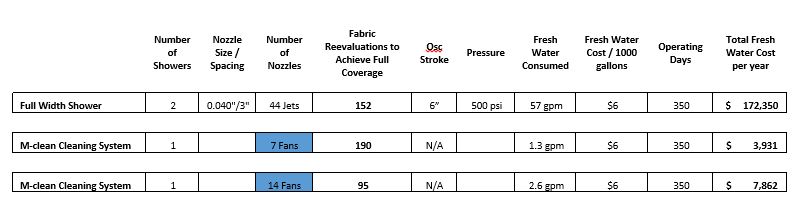

Outer Forming Fabric Cleaning: Water Consumption Cost Analysis

The fabric has a flooded nip shower followed by two high-pressure showers (roll side and sheet side) at 500 psi followed by a sheet side high-pressure fan shower at 400 psi. The recommendation was to replace two high-pressure needle jet showers with one M-clean tissue fabric cleaning system, improving permeability profile on the fabric and saving water.

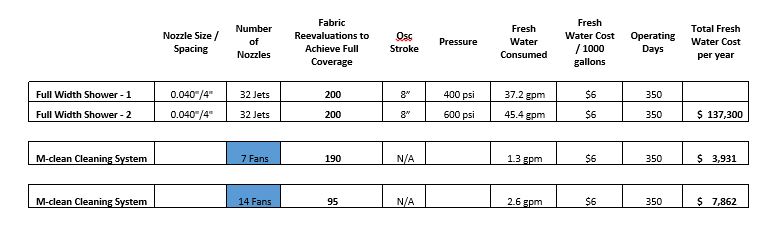

TAD Fabric Cleaning: Water Consumption Cost Analysis

The fabric has a flooded nip shower followed by a chisel shower and two high-pressure showers (roll side and sheet side. The recommendation is to replace two high-pressure needle jet showers with one M-clean tissue fabric cleaning system, improving spot cleaning, stickies removal, permeability profile on the fabric and saving water.

In summary, the traversing shower can be used with the same or even better cleaning frequency when compared to the full-width showers but operates with much higher efficiency and with at least 96% less water consumption. The payback based on water savings alone when using the M-clean tissue fabric cleaning system can be less than two years.