Torquing and Retorquing Best Practices for Kadant Unaflex Expansion Joints

Proper handling and installation of expansion joints are crucial to the performance and durability of the expansion joint. A critical step in the installation of your expansion joint is the torquing of the bolts. It is recommended that with each installation a new full complement of adequate hardware is used.

|

Retaining Ring / Flange Material |

Recommended Bolt Grade |

|

A34 Carbon Steel |

A193-B7 |

|

304 Stainless Steel |

A320/A320M Class 2B w/ 194/A 194 M Grade 8 or 8A |

|

316 Stainless Steel |

A320/A320M Class 2BM w/ 194/A 194 M Grade 8M or 8MA |

For other bolt materials, ensure the bolting material strength properties exceed the calculated bolt stress values. It is highly recommended that flat washers be used on both sides of the bolted connection. Bolts are tightened with a calibrated torque wrench to the specified torque values. Anti-seize compounds may cause variation in the torque values.

When bolting dissimilar materials, tighten to the recommendations of the component material with the lowest torque value. Using higher torque values may result in the deformation of the “softer” material.

24 hours after the initial installation, a retorquing of the expansion joint should be administered. This may also be done after the first thermal cycle. Systems intended for operation at elevated temperature levels, it is recommended that hot water be cycled through the system at the maximum operating temperature to allow for a full thermal cycle to occur (often 24 hours or more). The retorquing should take place after the system has cooled. It is recommended that retorquing of the system be an annual maintenance assignment.

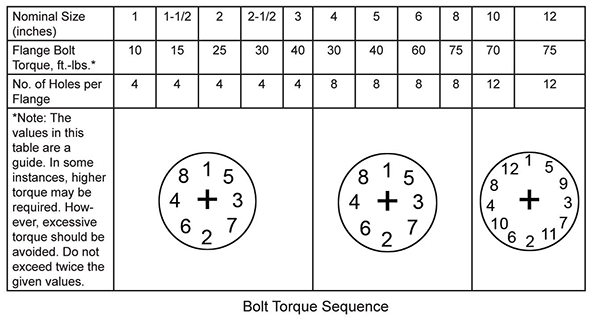

Bolt tightening patterns should be followed to ensure proper alignment and fit of the flange to the existing pipe. Similar to changing a tire, you want to tighten bolts at opposite ends of the flange.