Steam Joints for the Corrugating Industry

Rotary steam joints have been a part of the corrugating manufacturing process since the 1930’s. Since then, there have been significant advances in sealing technology, rotary joint design, and materials to extend the application range of the conventional pressure-type rotary joint.

Traditionally, the corrugating industry has used self-supporting rotary joints with pressure-type seals made from resin-impregnated carbon graphite seal rings. This style of rotary joint has worked well with traditional corrugating applications that run slower speeds.

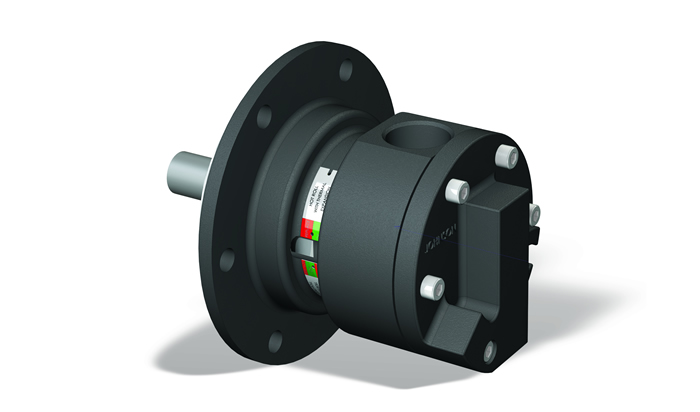

However, with modern corrugating machines that have the capability of running faster with frequent weight changes, rotary joint designs have evolved to allow for greater flexibility to accommodate a wider range of operating conditions. Rotary joints supported with brackets or rods with balanced seal technology proves to be a better solution for these types of modern-day applications. Balanced seal technology reduces the load on the rotary joint seal leading to improved seal life and reliability. Another feature of the bracket or rod-supported rotary joints is the inherent safety they offer by “securing” the rotary joint to the machine. Newer rotary joint technology no longer requires special guards to be built to secure them to the machine because with the new bracket and rod-supported designs rotary joints no longer move away from the machine as the seal ring wears. The newer technology also allows for adjustable syphon clearance from outside the roll, an indicator for seal ring wear, and reduced operating torque.

However, with modern corrugating machines that have the capability of running faster with frequent weight changes, rotary joint designs have evolved to allow for greater flexibility to accommodate a wider range of operating conditions. Rotary joints supported with brackets or rods with balanced seal technology proves to be a better solution for these types of modern-day applications. Balanced seal technology reduces the load on the rotary joint seal leading to improved seal life and reliability. Another feature of the bracket or rod-supported rotary joints is the inherent safety they offer by “securing” the rotary joint to the machine. Newer rotary joint technology no longer requires special guards to be built to secure them to the machine because with the new bracket and rod-supported designs rotary joints no longer move away from the machine as the seal ring wears. The newer technology also allows for adjustable syphon clearance from outside the roll, an indicator for seal ring wear, and reduced operating torque.