How to Recover From Flooding in Paper Dryers

When flooded dryers are identified during machine production, and if these issues are steam system related issues, there are several actions that can be taken to restore condensate flow and get the paper dryer back to normal operation.

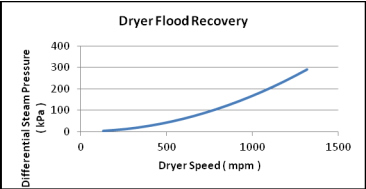

- Increase the relevant dryer group dP by increasing the dP set-point. This will result in steam being vented to the atmosphere or to a condenser, if one is installed. For rotary syphons, the dP set-point needs to be increased to above the flood recovery dP for the speed under consideration. The “Dryer Flood Recovery” graph shown to the right illustrates the increase in the flood recovery dP versus dryer speed. For stationary syphons, a dP of above 50 to 60 kPa should be sufficient to evacuate the accumulation of any condensate from within the dryers.

- Continue checking the condensate sight glasses installed on each dryer within the dryer group. Condensate evacuation commences when the syphon operating dP equals the syphon flood recovery dP. Condensate will then clearly be visible and flowing freely through the sight glass. This flow will gradually change from a continuous stream of condensate to a pulsating atomised mixture as normal syphon operation is restored.

- Continue to monitor the separator level and the level control valve position. Maintain the elevated dP until both measurements return back to the long term trend values before reducing the dP to the recommended value. This operation could take anything from 5 to 15 minutes before the separator tank level reaches its original set-point.

- A reduction in the steam pressure of the master group controlling the sheet moisture or an increase in machine speed will be confirmation that the dryers have recovered from their flooded state and are evacuating condensate normally.

- Shell and sheet temperature measurements should be taken to confirm that all dryers are functioning correctly.