What are Rotary Joints & Rotary Unions?

A rotary joint, also referred to as a rotary union or rotating union, is a rotary sealing device that connects rotating equipment to fixed piping for the transfer of steam, water, thermal oil, coolant, hydraulic oil, air, and other media. Rotary unions can be designed with multiple passages and manage multiple media types simultaneously. In these cases, a soft seal such as an O-ring is used to prevent the fluids from “crossing-over” into another passage. Soft seal multi-passage rotary unions are used in a variety of industries and applications including oil and gas, food and beverage, aerospace, robotics, and medical devices. In some applications, the rotary union is fitted with slip rings for transmitting electrical signals as well as hydraulic power.

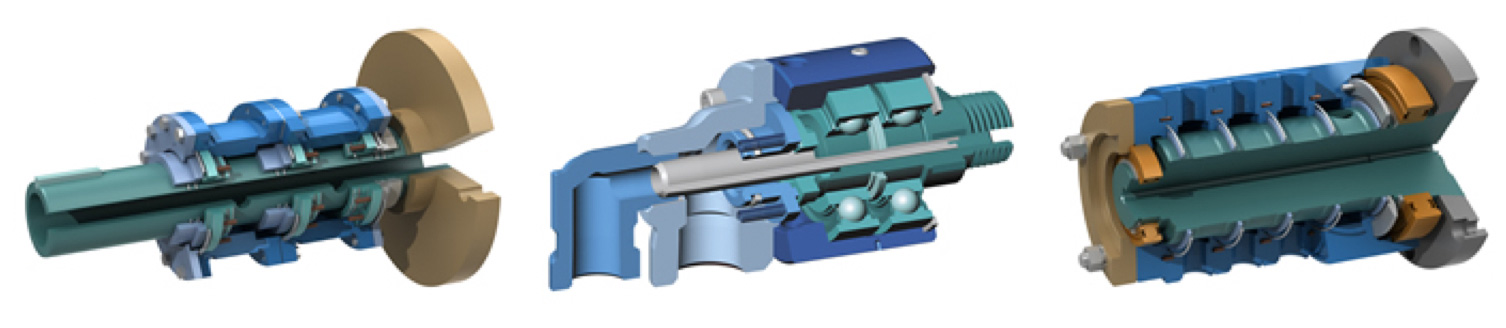

With conventional rotary joints, a spring-loaded seal is used to keep the fluid or gas medium from being dispersed into the atmosphere. The spring is used in the rotary joint to maintain the initial internal seating, and the rotary joint is pressure-sealed once in operation. Low-pressure or vacuum service relies on the spring force to create the seal. Conventional rotary joints are either self-supported with the use of an internal carbon guide, or external-supported using rods or a mounting bracket.

Balanced seal rotary unions are generally used with fluid service (e.g. water, coolant, etc.), but can be used with steam and other gases. Balanced seal technology relies on optimizing the spring pressure to create a positive seal within the rotary union. The operating pressure of the media has little, if any, effect on the seal load. Balanced seals are typically flat face seals and the rotary unions are supported by ball bearings.

The seals are the main wearing components of a rotary joint and rotary union. During operation, seals can experience internal loading forces from fluid pressure, as well as friction from contact between the sealing faces. Factors related to the machine speed, temperature, and media used can also affect the life of the seal ring. To a large extent, a rotary union is only as good as its seal package. Poor quality seals naturally wear out more rapidly, leading to an increase in maintenance, downtime, and repair cost. When a seal fails, media escapes and the efficiency of the entire heating or cooling process suffers. All of this makes the actual replacement cost of the seal just a small portion of the total cost of a seal failure.