Why Do My Steam Coils Freeze in the Winter?

A steam trap, which traps steam inside the steam coil and allows condensate to pass, is commonly installed on the outlet of the steam coil.

To prevent coils from freezing you need to understand how the system works. As the steam coil discharge air temperature approaches the setpoint, the steam control valve starts to close, reducing the steam pressure to the steam coils.

To drain the steam coil, a positive differential pressure needs to be maintained across the steam trap. If the condensate is being lifted out of the steam trap into an overhead return line, there may not be enough steam pressure in the steam coil to push the condensate out of the steam trap and into the overhead return line.

If the condensate cannot drain completely from the steam coil, the cold outside air could lower the condensate temperature enough to cause the condensate to freeze. When water freezes it expands in volume, resulting in ruptured tubes in the steam coil.

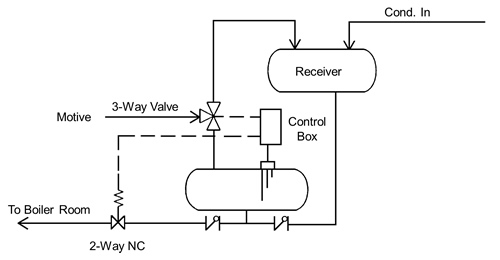

If you experience coil freezing, a couple of options would be to have the steam traps drain to a condensate pump so it can push the condensate into the overhead return line or install a Liqui-Mover PumpTrap™ system.

Condensate pumps typically have a vented receiver so the temperature of the condensate is low enough so as to not cause pump cavitation, around 180° F. A PumpTrap system is a pressure power pump utilizing an automated 2-way trapping mechanism at the outlet of the pressure power pump. The steam trap on the outlet of the steam coil is removed and replaced with a pump-trap combination.

A PumpTrap system is used on non-vented (closed) applications when collecting condensate from a single steam coil and venting of flash steam is eliminated.

Installation of a vacuum breaker and air eliminator will also assist in condensate drainage and better heat transfer of the steam coil.