Can Filtration Equipment Cost-effectively Reclaim White Water in Systems With a Variability in Solids?

Selecting filtration equipment that performs efficiently under the dynamic process conditions of paper machine white water loops can be a challenge for many papermakers. Variability in furnish, paper grades and the operating conditions of the machine, can lead to large swings in the type and amount of solids that must be removed from the white water before it can be reused in the process.

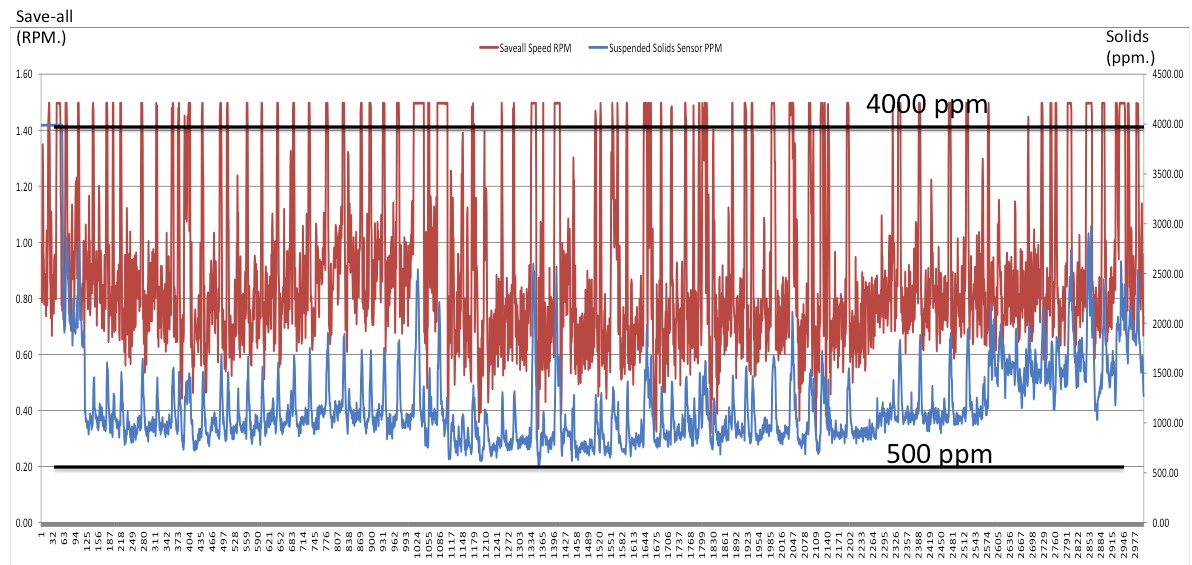

The following graph depicts a typical save-all system used to recover fiber and begin the process of filtering the water for reuse. The save-all speed (red line) is adjusted to try to accommodate the changes in solids type and quantity coming to the save-all. The (blue line) indicates the amount of solids coming out of the clear leg of the save-all. It is this clear leg water that is typically reused after finer filtration is done. In this example the finer filtration equipment that would be selected must be capable of handling a minimum of 4000 ppm of solids, with a range of 500-4000 ppm.

Many pieces of equipment in use today will lose performance in these conditions, and some may even stop working all together when faced with such variability. When this happens, mills experience upsets in their filtered water system and are forced to resort to adding expensive freshwater to make up for the lack of filtered water. To address these issues and provide papermakers with the ability to use more white water in the process, Kadant Solutions recently launched the RotoFlex™ resource recovery strainer.

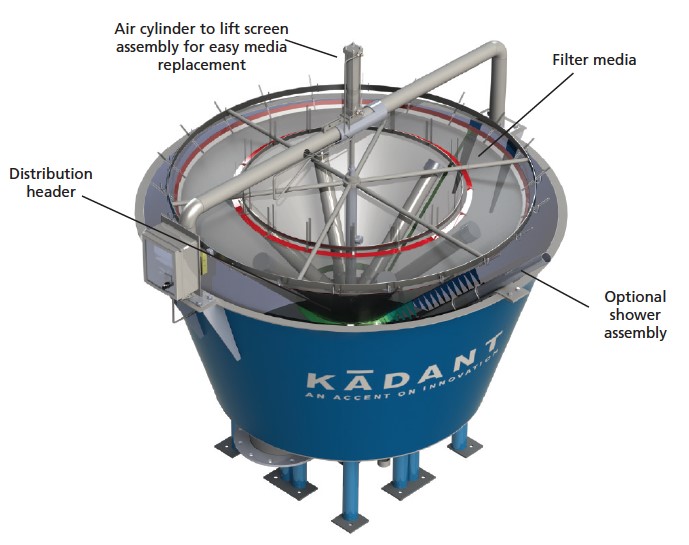

The RotoFlex resource recovery strainer features a flexible conical-shaped media that ranges from 60 -325 mesh, depending on solids type and quantity. The white water is directed onto the inside of the screen at a controlled angle and utilizes the feed pressure from the distribution header to rotate and flex the screen. As the white water passes through the media, the solids slide down the inside of the cone to the reject port. The constant flexing of the fabric allows the screen to adapt to a wide range of solids up to 10,000 ppm while maintaining performance.

The RotoFlex resource recovery strainer features a flexible conical-shaped media that ranges from 60 -325 mesh, depending on solids type and quantity. The white water is directed onto the inside of the screen at a controlled angle and utilizes the feed pressure from the distribution header to rotate and flex the screen. As the white water passes through the media, the solids slide down the inside of the cone to the reject port. The constant flexing of the fabric allows the screen to adapt to a wide range of solids up to 10,000 ppm while maintaining performance.