Pressure Powered Pump Alternative Reduces Maintenance

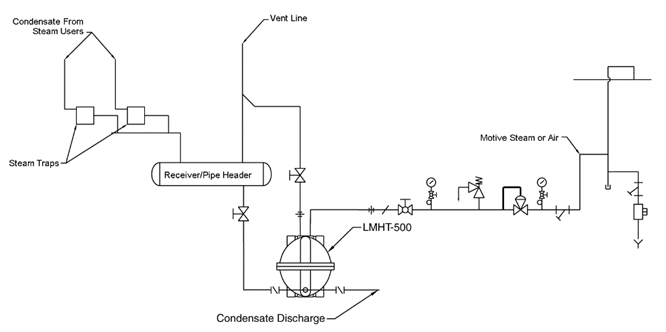

There are thousands of electric centrifugal pumps in service used to pump condensate. These pumps are either simplex or duplex condensate pump units and operated with a mechanical float switch assembly. Many centrifugal pumps can handle condensate temperatures up to 200° F. Some pump manufacturers offer higher temperature seal packages, but may also require NPSH for the pumps to operate without cavitation. Duplex pump units are frequently used due to the fact that centrifugal pumps require more frequent maintenance as the condensate temperature is often above 200° F. To lower the condensate temperature below 200° F for pumping, the receiver is vented to atmosphere and valuable heat energy is allowed to flash. It is important to be sure the centrifugal pump can generate a high enough discharge pressure to elevate the condensate into the common return line and still maintain the desired rated capacity. A typical condensate pump schematic is shown in the image above.

An alternative to electric centrifugal pumps is a pump-less, pressure-powered condensate pump. Pressure powered pumps are designed to handle condensate temperatures up to 365° F independent of NPSH and are many times designed as “closed” systems that do not flash or vent steam under normal operating conditions. Pumping action is achieved using a mechanical non-electric float or a float-free 2-probe conductance level control. Steam or compressed air is the motive pressure for returning the condensate. Discharge pump pressure is determined by the motive pressure supplied to the condensate pump, normally 15-20 psig higher than the backpressure. Fewer moving parts, no mechanical seals, and energy efficiency are commonly cited as benefits of a pressure-powered pump. A typical schematic of Kadant Johnson’s Liqui-Mover pressure powered pump and pipelines is shown below.