Ensuring Safety and Reliability in Pressure Equipment: The Vital Role of PED and Original Spare Parts

With pressure equipment, adherence to standards is important for ensuring safety, performance, and legal compliance. At the core of the regulatory environment stands the Pressure Equipment Directive (PED), a set of rules established by the European Union to regulate the design, manufacture, testing and conformity assessment of pressure equipment.

Why is PED Crucial?

The Pressure Equipment Directive (PED) plays a crucial role in ensuring the safety, standardization, and legal compliance of pressure equipment within the European Union (EU). Firstly, PED prioritizes safety by establishing specific requirements for pressure equipment, aiming to mitigate the risks associated with accidents, injuries, and property damage resulting from equipment failure.

Secondly, by providing a harmonized set of rules, PED ensures uniform safety standards across the EU, facilitating the smooth movement of pressure equipment within the European market.

Thirdly, compliance with PED is not only promoted but mandatory for manufacturers and suppliers of pressure equipment in the EU, demonstrating an ongoing commitment to safety and avoiding potential legal consequences.

Lastly, for PED products in the European Economic Area, look for the CE mark, which designates compliance with EU safety standards.

The connection between the Pressure Equipment Directive (PED) and the utilization of original parts for industrial machinery is crucial for ensuring the integrity, safety, and compliance of pressure equipment within the European Union (EU). The PED sets strict standards for the design, manufacture, and conformity assessment of pressure equipment, emphasizing the importance of complying with these guidelines for increased safety.

Using original parts, designed and tested by the same manufacturer as the equipment, aligns with the PED's principles. Original parts not only ensure compatibility and optimal performance but also play a crucial role in maintaining the safety and reliability of industrial machinery.

Furthermore, compliance with PED is often a legal requirement in the EU, and the use of original parts is a proactive measure to uphold these regulations, preventing potential risks associated with non-original or counterfeit components. This symbiotic relationship between PED and original parts underscores the commitment to safety, longevity, and regulatory adherence in the realm of industrial machinery.

In addition to this, there are also many risks in using non-original spare parts in critical components such as rotary joints:

- Safety Hazards: Non-original parts may lack quality and safety standards, elevating the risk of equipment failure and posing dangers to personnel and the environment.

- Compatibility Issues: Deviations from original specifications may lead to compatibility issues, affecting overall equipment performance and potentially causing damage.

- Reduced Reliability: Non-original parts compromise equipment reliability, contributing to unexpected breakdowns, increased downtime, and higher maintenance costs.

- Warranty Voidance: Using non-original parts may void warranties, leaving users financially responsible for repairs and without manufacturer support.

- Loss of Certification: Non-original parts may result in non-compliance with regulatory standards, leading to the loss of certification and legal consequences.

- Unknown Quality: Lack of quality control in non-original parts can lead to unpredictable and hazardous behavior in equipment functionality.

- Shortened Equipment Life: Parts not meeting original specifications accelerate wear and tear, requiring more frequent repairs or premature replacement.

- Increased Operating Costs: Initial cost savings with non-original parts may result in higher long-term costs due to increased maintenance, downtime, and potential replacements.

How to mitigate risks?

To ensure the safety, reliability, and consistent performance of pressure equipment, end-users are advised to follow the manufacturer's recommendations and opt for original spare parts, designed and tested to integrate optimally with their specific equipment. This proactive approach reduces risks, meets standards, and ensures the longevity of pressure equipment throughout its operational life.

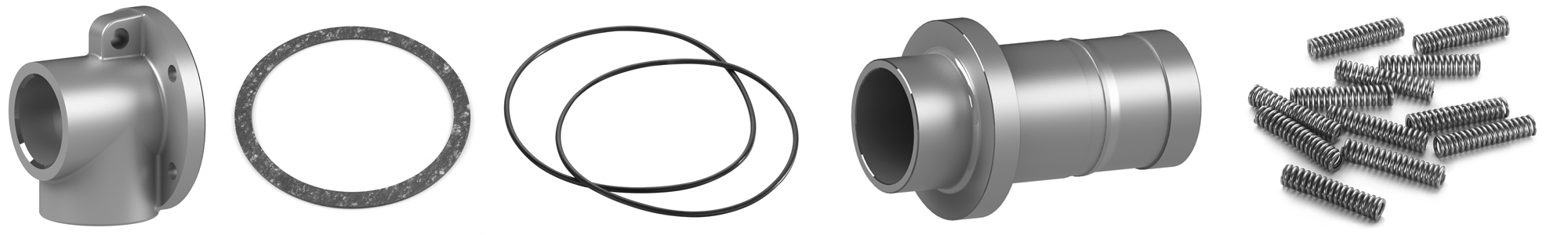

Recognizing the potential risks associated with non-original components, we proudly offer a comprehensive range of spare parts, specially designed and tested for our rotary unions.

For carbon-guided rotary joints contact us to receive information on:

Seal ring / Gasket / Guides / Head / Nipple / Springs

Or you can ask for the “cartridge” that includes all parts mentioned above plus the body of the union.

For ball bearing rotary joints contact us to receive information on our seal repair kits that include:

Seal ring / Counterseat / Springs

For paper and corrugating rotary joints such as PT™-PTX®-PT2X™-CorrPro® steam joints, we have ready-to-use solutions for:

Seal ring / Complete repair kits / Wear plate / Piston assembly

Follow Us on LinkedIn

Connect with Kadant Johnson Europe on LinkedIn to learn more about our employees, products, and services.