How to Clean a Vacuum Breaker

Vacuum breakers provide a simple, dependable way to relieve any unwanted vacuum condition that may develop in a closed vessel or pipeline. In latent terms, vacuum breakers function as a “one-way-door” that allows air or other mediums to pass through the threshold and seal the door shut, preventing backflow. When installed improperly, they can collect debris on the stainless-steel ball, between the stainless-steel ball and O-ring, and in the cage. The debris reduces the effectiveness of the vacuum breaker, which can lead to catastrophic failure, equipment damage, or serious injury. A proper cleaning is required to remove the debris.

Problem:

A customer was performing their system checks before startup and noticed debris in a few of their vacuum breakers. The customer removed the clogged vacuum breaker from their system and proceeded to blow pressurized air into the cage in an attempt to remove the debris. This solution will potentially shorten the lifecycle of the vacuum breaker by dislodging the O-ring inside. There is a better solution that will not harm the O-ring or shorten the vacuum breaker’s lifecycle.

Solution:

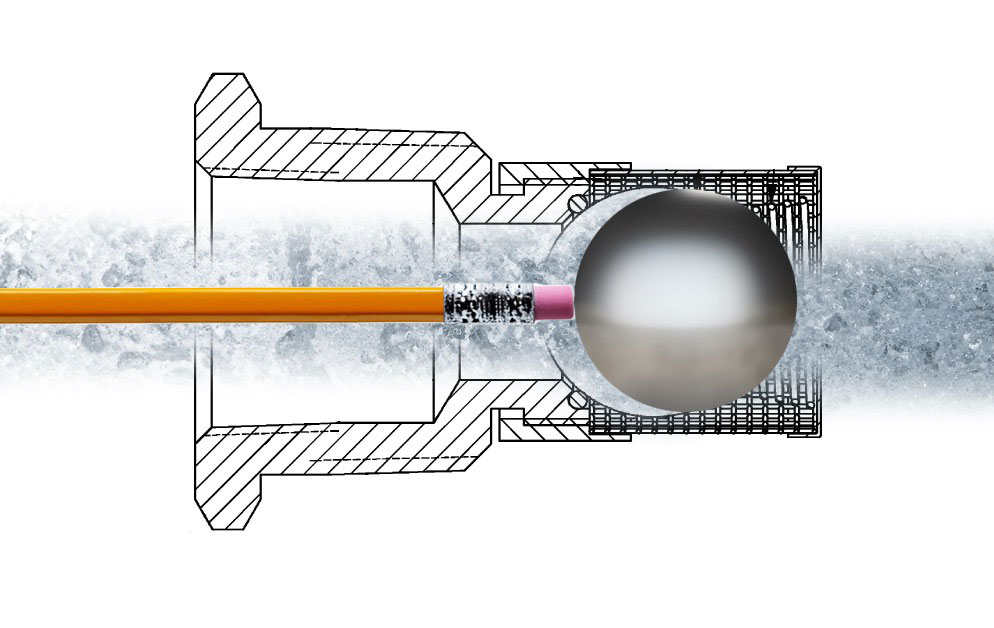

Kadant Johnson recommends cleaning a vacuum breaker using cool, clean tap water. After safely removing the vacuum breaker, use a soft, blunt object (such as the eraser on a pencil) to push the stainless-steel ball into the spring. Doing this will open the valve, allowing the low-pressure tap water to flush the debris away from the cage and stainless-steel ball. Once all the debris is removed, the vacuum breaker is ready to be put back into operation. Following this procedure will minimize the risk of damaging the vacuum breaker and diminishing its operation capabilities.