Preventing Steam System Damage from Improper Flexible Metal Hose Installations

Proper flexible metal hose installations prevent stress on rotary joints and unions as well as connected piping due to thermal expansion, vibration, and misalignment. Improper flexible metal hose installations can damage rotary joints, shift steam headers, and wreak havoc on steam systems. If flexible hose is sized too long, it will push equipment apart as it is pressurized. This is because a flexible hose becomes rigid and expands when pressurized. If it is sized too short, it will be in tension and act to pull equipment together. The secret to properly installing flexible hose is not sizing it just right, the secret is creating a configuration that allows variances in lengths, offsets, thermal expansion, misalignment, and vibration.

Proper flexible metal hose installations prevent stress on rotary joints and unions as well as connected piping due to thermal expansion, vibration, and misalignment. Improper flexible metal hose installations can damage rotary joints, shift steam headers, and wreak havoc on steam systems. If flexible hose is sized too long, it will push equipment apart as it is pressurized. This is because a flexible hose becomes rigid and expands when pressurized. If it is sized too short, it will be in tension and act to pull equipment together. The secret to properly installing flexible hose is not sizing it just right, the secret is creating a configuration that allows variances in lengths, offsets, thermal expansion, misalignment, and vibration.

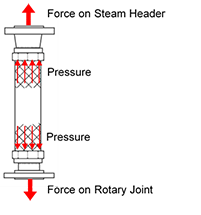

Too Long

Flexible hoses that are sized too long are often installed by compressing them. Once pressurized, force acts on both ends of the hose to lengthen it until the stainless-steel braids are fully extended. The force acting to extend the hose can be tremendous as the flexible hose acts as a rigid tie rod. To illustrate this, Mark Franks, director of services, shared his experience,

Flexible hoses that are sized too long are often installed by compressing them. Once pressurized, force acts on both ends of the hose to lengthen it until the stainless-steel braids are fully extended. The force acting to extend the hose can be tremendous as the flexible hose acts as a rigid tie rod. To illustrate this, Mark Franks, director of services, shared his experience,

“We were installing rotary joints at a papermill in North Carolina. We were using 3” steam hoses that were all compressed during installation. At startup, the combined thrust lifted the steam header off its supports. It was a 10 inch diameter pipe, 40 feet long. The mill rushed in new flexible hoses to eliminate the floating steam header.” Expanding hoses also put significant side loading pressure on rotary joints and cause premature wear. This is particularly true in self-supported rotary joints that do not have as much lateral support as bracket supported rotary joints.

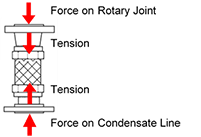

Too Short

Flexible hoses that are sized too short also cause damage to steam equipment. As Rick Lull, senior applications engineer, recently shared, “I was at a customer that had a self-supported steam joint that kept wearing out prematurely. We went to their facility to help rebuild the existing joint and noticed a jack was used to lift the condensate return line so the flexible house could reach the rotary joint. When they released the jack, the condensate line hung from the flexible hose and put a tremendous load on the rotary joint. We immediately knew the reason the rotary joint was failing prematurely.

Flexible hoses that are sized too short also cause damage to steam equipment. As Rick Lull, senior applications engineer, recently shared, “I was at a customer that had a self-supported steam joint that kept wearing out prematurely. We went to their facility to help rebuild the existing joint and noticed a jack was used to lift the condensate return line so the flexible house could reach the rotary joint. When they released the jack, the condensate line hung from the flexible hose and put a tremendous load on the rotary joint. We immediately knew the reason the rotary joint was failing prematurely.

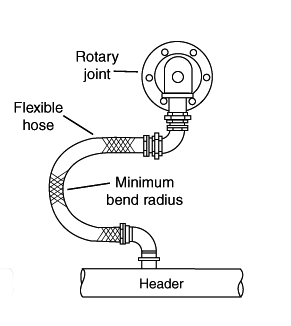

Just Right

To avoid a steam hose that is too short, too long, or unable to accommodate thermal expansion, vibration, and misalignment, a minimum bend radius or a compound (or two hose) configuration is recommended. This avoids the need to measure the length “just right” and prevents steam equipment loading caused by a single straight flexible hose. The minimum bend radius and compound flexible hose configurations allow the flexible hose to absorb axial and radial misalignment, and equipment movement and vibration. A properly configured flexible metal hose installations will maximize the life of rotary joints and other steam equipment.

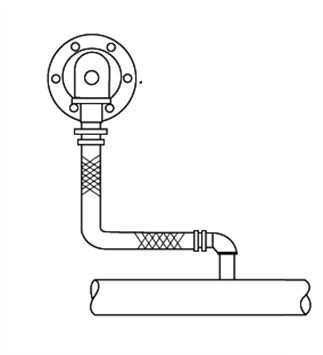

Minimum Bend Radius Configuration

Compound Configuration