What’s this thing for? Measuring Seal Wear

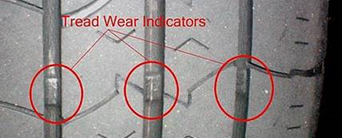

Tires are critical to the safe operation of every vehicle on the road. While it is not difficult to tell when a tire is flat, knowing when it is time to replace your tires can be a challenge. There have been various methods for determining when tires should be replaced, including rulers and even coin tricks. Manufacturers now use wear bars that are embedded between the tread ribs at 1/16” height. When the tread becomes flush with the wear bars, it is time to replace the tires.

Similar to tires, Kadant Johnson rotary joint seal wear can be measured. In this post, I present a few ways seal life can be measured.

Many self-supported rotary joints have a wear indicator machined on the nipple of the rotary joint. When new, the indicator lines up with the edge of the wear plate. As the seal wears, that indicator becomes more exposed, until it reaches full wear at a dimension specific to the rotary joint size. For example, the 1-1/2” ELSN™ rotary joint has 0.33” of allowable seal wear when new. Once the wear indicator is 0.33” from the edge of the wear plate, a seal replacement should be scheduled.

Most internally compensated rotary joints have a tool that is used for measuring seal wear. When new, the tool fits tightly against the wear plate. When worn, the indicator sticks out and ultimately shows red when the seal is worn. For example, the 2500LNIC rotary joint below has 0.33” of allowable wear and the visible red marking on the measurement tool indicates the seal should be replaced.

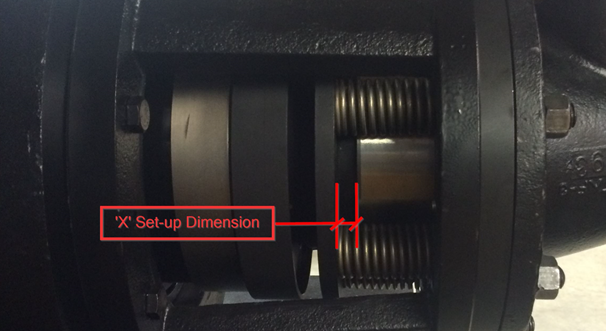

PT™ and PTX® steam joints are installed with an initial setup, or ‘X’ dimension that is recorded at the time of installation. As shown in the picture below, this is a simple measurement between two surfaces. As the seal wears, the setup dimension increases to compensate for seal wear. A 9750PTX steam joint will has a set-up dimension of 0.30” when new. When this grows to 0.75”, the seal has reached the end of its useable life and must be replaced.

Now that you know “what this thing is for” you can develop a strategy for checking seal wear and getting ahead of joint repairs before leaks have a chance to impact production and unplanned maintenance downtime. Please contact us for drawings and allowable seal wear specific to your Kadant Johnson rotary joint.