Improving Flaker Productivity - a Case Study

Often the goal for roll cleaning is to prevent contaminants from getting into the finished product. However, for the flaking industry, application-specific doctor blades provide a different function. In everything from potato starch flaking to pharmaceutical uses, the goal is to efficiently remove the product from the roll and generate maximum yield. So what benefit do roll cleaning and scraping technologies offer the flaking industry? The following case study illustrates how a specialized blade holder and flaking blade significantly increased productivity and decreased downtime.

Often the goal for roll cleaning is to prevent contaminants from getting into the finished product. However, for the flaking industry, application-specific doctor blades provide a different function. In everything from potato starch flaking to pharmaceutical uses, the goal is to efficiently remove the product from the roll and generate maximum yield. So what benefit do roll cleaning and scraping technologies offer the flaking industry? The following case study illustrates how a specialized blade holder and flaking blade significantly increased productivity and decreased downtime.

Challenge

A US-based specialty chemical producer used OEM clamp-style holders on its drum flaker. These holders were difficult to work with and required up to three hours of downtime per blade change. And because the blades were clamped into place, there was no allowance for thermal expansion resulting in ripples across the roll. To avoid rippling, thicker blades (2.4 mm) were used that further limited the flexibility and conformance of the blade to the drum, which led to uneven wear and grooving of the drum surface. Additionally, the holders and blades did not oscillate and the blades were not adjustable leading to blade misalignment and degraded flaker performance over time.

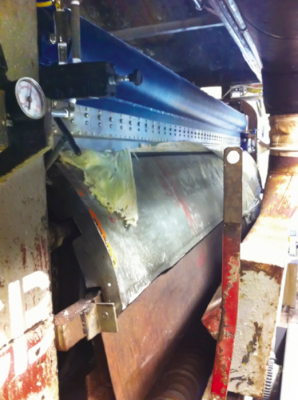

Solution The OEM-supplied scraper assembly was replaced with a new Kadant Flaking Doctor System which included the AccuFlake™ blade holder, ProFlake™ blade, and Varimatic™ oscillator.

The OEM-supplied scraper assembly was replaced with a new Kadant Flaking Doctor System which included the AccuFlake™ blade holder, ProFlake™ blade, and Varimatic™ oscillator.

Results

The time required to change the doctor blade was reduced by 98 percent, from three hours to three minutes, and the easy end-removal design made the blade change much safer. Flaking consistency and product yield increased due to the high conformability of the thin-but-strong ProFlake. The thinner blades required less load on the blade, which meant less wear on the drum. And, finally, the new doctor system provides oscillation, improving flaking efficiency, and micro adjustability of the doctor blade to ease set-up and optimize blade angle for maximum yield.

Market Insights

AccuFlake blade holders are specifically designed for drum flakers to provide safe, fast, and easy blade changes. ProFlake blades offer longer operating life and improved control to increase productivity and decrease downtime.

Click here to learn more about the AccuFlake blade holder and ProFlake blade.