Nanotechnology Blade Breakthrough Follows Call for Step Change in Performance

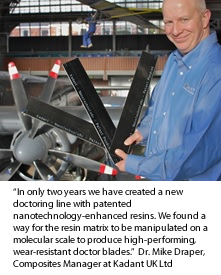

Dr. Mike Draper is Composites Manager at Kadant UK Ltd.

Five years ago our CEO, Jon Painter, brought the Kadant R&D teams together with a mission in mind: he encouraged step change technologies vs. incremental gains. For my team in the UK, this meant a revolutionary step forward for doctoring. Blades tougher than steel. Blades capable of withstanding brutal contaminated conditions; providing high value and excellent performance to our customers.

We were intrigued by a speculative press article in the UK regarding nanowires that claimed that they were both lighter and stronger than steel and could potentially be made long enough to reach the moon. We wondered if we could exploit the unique benefits of these or similar materials. Withstanding extremely harsh conditions during coating calls for blades fit for this tough environment. My own background with polymeric science told me that this hunch was more than a hunch. It was a starting point and fit perfectly with the new visionary strategy of step change technologies that was being encouraged right from the top. After all, nanowires are really just long lines of nanoparticles.

Brainstorming mixed with motivation

As brainstorming from the global team began, each of us was highly motivated to seek new solutions. The more I investigated a range of nanoparticle technology options, the more excited I became. Based on collective and individual research, our team conducted a lot of trial and error work, having good results followed by inconsistent results. Our initial findings with nanotechnology based coatings for doctor blades showed us that variants in our formulations produced dramatically different results. We worked closely with our U.S. colleagues on a constructional change, that not only made machining easier, but actually further enhanced the overall product performance, ultimately providing a two-fold solution—longer doctor blade life and greater roll cleanliness.

Surfing for solutions

Surfing for solutions

We continued to look at aerospace composites and automotive parts, and expanded the review to consider nanoparticles used in surfboards, hockey sticks, and cosmetics to find the best solution. Experimenting can be frustrating at times. To get the right materials to perform in the right way for our purposes proved very challenging. Visits to composite and nanotechnology conferences and exhibitions became the norm. Direct contact with scientists from other industries was also helpful.

When you are seeking a step change, you can’t accept an incremental improvement. Otherwise our products would have been only a little better than “me-too” doctor blades. We decided to seek trial opportunities on the most difficult positions and machines, which were known to have caused problems in the past.

Seeking the Worst Places for Trials

A board producer in China using highly contaminated recycled waste managed to make satisfactory products, but their composite doctor blades were destroyed in no more than two days. Stickies were the worst of the worst, so the challenge was enormous. Our Chinese team placed our experimental nano-composition blades on the machine. Ten days into the trial, it was time to change our doctor blades! We beat our own expectations, and won a steady customer.

Shutdown to Shutdown, Running Without a Blade Change

We lined up other trials in North America and Europe, and achieved the kind of “step change” results we set out to accomplish. Our aim to allow continuous runs from startup to shutdown without changing the blade is now well underway.

Longer life really comes from cleanliness, made possible by the precision of our blades. High level carbon fiber nanotechnology-enhanced doctor blade models are ideal for the heavy-duty positions. This includes early dryers, where heat hits the stickies and bonds them to rolls. Blades on center presses and calender stacks work best with the glass and hybrid carbon and glass and nanotechnology-enhanced blade models.

Value and Cost Performance

Not only are Kadant nanotechnology-enhanced blades lasting longer and improving sheet quality, they are replacing more expensive competitive carbon fiber blades. Our blades utilize entirely new polymer-based formulations, which are more cost effective. With strong references in China, Southern Europe and North America, growth is ramping up.

Why the Breakthrough?

Why the Breakthrough?

Sometimes breakthroughs come from what you choose not to do. Across the globe we came together as one. There was never a “not invented here philosophy.” My experience with chemistry, and applying technology in new ways, was my primary contribution. But none of this could have happened without undying back up and support. Internally, top down, bottom up, and all regions of the world, deserve the credit. And so do our customers, who allowed trials to prove out our concepts.

Next Steps

In only two years we have created a new doctoring line with patented nanotechnology-enhanced resins. We found a way for the resin matrix to be manipulated on a molecular scale to produce high-performing, wear-resistant doctor blades. What’s next? The next step change, of course! This is just the first in a number of step change technologies that we will be bringing through over the coming years. Many of these will build on what we have learned and incorporate nanotechnology to further push the boundaries of this technology. Kadant has a very exciting future.

Learn more about Kadant’s nanotechnology-enhanced doctor blades.