Paper Mill Insights Behind the New PT2X™ Rotary Joint

Insights

Paper mills continue to focus on increasing uptime and operating speed. This is to increase profits and meet their customer demands. Increased uptime also helps offset the need for skilled maintenance personnel as baby boomers retire and budgets shrink.

Uptime improvements are achieved through greater subsystem durability and preventive maintenance. Many mills offer challenging physical environments that run 24 hours a day, making durability and preventive maintenance even more important and difficult to achieve.

Some mills are achieving faster-operating speeds with higher steam pressures and temperatures in the dryer section. New steel dryer rolls can be rated at 200 psig, a 25% increase over typical cast iron dryer rolls.

Increasing dryer section uptime and operating speed are competing requirements. Higher production rates increase wear and tear on components due to mechanical speed. Higher pressures and temperatures required to increase drying rates also wear equipment more quickly. Kadant Johnson’s product development team’s challenge was to deliver both increased durability, pressure, and temperature capability.

Increasing dryer section uptime and operating speed are competing requirements. Higher production rates increase wear and tear on components due to mechanical speed. Higher pressures and temperatures required to increase drying rates also wear equipment more quickly. Kadant Johnson’s product development team’s challenge was to deliver both increased durability, pressure, and temperature capability.

Design Development

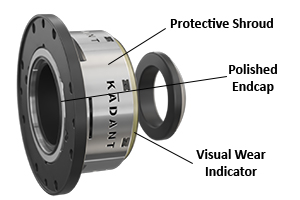

To develop the next generation rotary joints specifically engineered for paper mills, Kadant Johnson’s product development group first enhanced the robustness of the current, industry-leading PTX® rotary joint. A protective shroud was added to the wear cartridge to keep contaminants out. A polished stainless-steel endcap was designed to extend secondary seal life and a visual seal wear indicator was added to facilitate planned maintenance. The cartridge design allows existing PTX rotary joints to be upgraded and is easy to swap worn cartridges with new during planned maintenance.

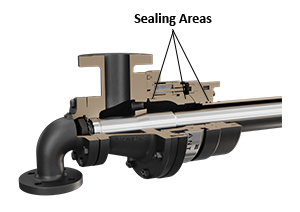

To accommodate high-pressure and temperature applications, the team developed an optional proprietary seal package that will durably operate at 200 psig. This seal packaged combined with the durability improvements make the high-pressure PT2X rotary joint unique to the industry.

To accommodate high-pressure and temperature applications, the team developed an optional proprietary seal package that will durably operate at 200 psig. This seal packaged combined with the durability improvements make the high-pressure PT2X rotary joint unique to the industry.

The PT2X rotary joint product team was able to deliver greater durability and pressure capability by always keeping papermill needs and insights at the center of the product development process.