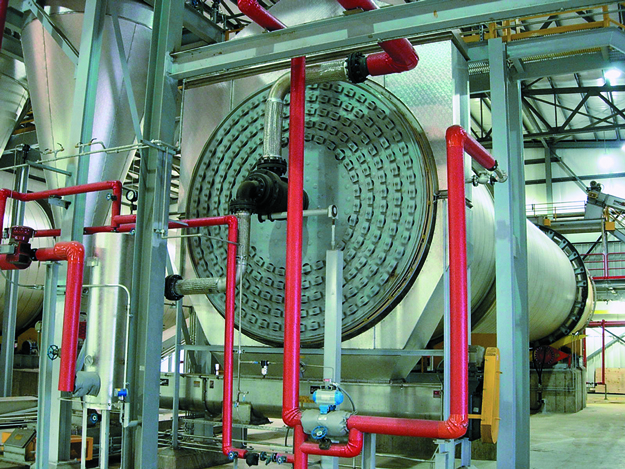

Rotary Joint Applications – Full steam ahead!

A rotary joint, also referred to as a rotary union or rotating union, permits the flow of various media from a supply pipe in to and/or out of rotating equipment. Heat transfer and hydraulic media typically used with rotary joints and rotating unions include steam, water, thermal oil, hydraulic oil, air, and coolant. It is worth the time to evaluate new applications as well as existing applications to ensure the right rotary joint is used. The critical application information includes:

Fluid type (steam, water, air, etc.)

Fluid type (steam, water, air, etc.)- Rotational speed

- Pressure

- Temperature

- Flow Rate

- Piping and equipment connection sizes

Selecting a rotary joint from a catalog is one option, but some applications require a detailed look to select the appropriate rotary joint. Kadant Johnson uses proprietary programs and its extensive application expertise to assess flow capacity and pressure drop as well as estimating seal life under the actual operating conditions. Based on that analysis, we recommend the appropriate rotary joint and seal technology for the application.

For existing applications, we compare your experience with rotary joint performance to our expectations. If you are experiencing diminished efficiency or a reduced rotary joint life, it is an appropriate time to review the application. You can run at the upper end of acceptable limits, but there is usually a negative impact on performance if multiple limits are reached. Perhaps your operation has changed enough that your rotary joint, which used to work quite well, is no longer the best option for your application. Perhaps you are interested in increased production which could result in operating at higher speeds and or temperatures. Selecting the appropriate rotary joint for your application will contribute towards optimal performance at the conditions you need to achieve your production goals.

Custom Rotary Union Solutions

Some applications are better suited for a non-standard rotary joint or a rotary joint in a different configuration. For these applications that require specialized solutions, our engineering team focuses on providing technology that meets the application demands. Your goal is our goal and we work closely with you to develop reliable, efficient, and technically advanced products that add value by improving the process and the quality of the end product.

Maximize production capacity, minimize maintenance costs, and improve reliability with the best rotary joint solution possible…full steam ahead!