A History of Forming Systems for Packaging Grades of Paper

For years, papermakers have looked for the best combination of drainage and formation in the early section of fourdrinier paper machines. The ability to maximize drainage without sealing the sheet and to control sheet activity over a wide range of basis weights have been challenges with increasing machine speeds and customer quality demands.

In the early days, the papermaker could only physically change conventional foil blades with different angles to affect the drainage / formation relationship. This balancing act, when draining too aggressively sealed the sheet and harmed formation opposed to draining too slowly which hurt couch consistency and production was an operating compromise. Changing blades also caused safety concerns for both personnel and equipment on wide, fast machines.

In the early days, the papermaker could only physically change conventional foil blades with different angles to affect the drainage / formation relationship. This balancing act, when draining too aggressively sealed the sheet and harmed formation opposed to draining too slowly which hurt couch consistency and production was an operating compromise. Changing blades also caused safety concerns for both personnel and equipment on wide, fast machines.

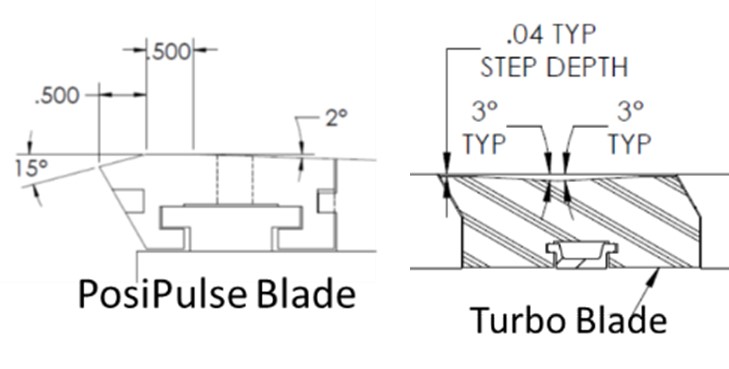

Changing foil blades was followed by a succession of new straight angle blade shapes to improve the energy (activity) put into the sheet slurry. The energy imparted by these blades is speed dependent, which over a wide basis weight range, again, required the papermaker to change them as they had with standard foils.

Changing foil blades was followed by a succession of new straight angle blade shapes to improve the energy (activity) put into the sheet slurry. The energy imparted by these blades is speed dependent, which over a wide basis weight range, again, required the papermaker to change them as they had with standard foils.

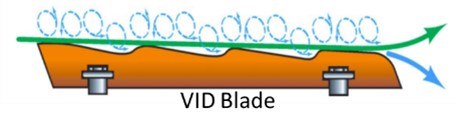

The next development to control drainage and activity came with the introduction of the VID™ (Velocity Induced Drainage) forming technology concept. The VID forming technology blade shape differed from previous blades by using curved surfaces (like an airfoil) to cause water to be intermittently pulled below the wire for drainage and re-injected into the sheet to re-fluidize the fiber slurry on top of the wire and improve formation. The curved shape of the blade surface was substantially more efficient than straight angle surfaces of standard foils causing the water to follow the blade surface in a controllable manner.

The next development to control drainage and activity came with the introduction of the VID™ (Velocity Induced Drainage) forming technology concept. The VID forming technology blade shape differed from previous blades by using curved surfaces (like an airfoil) to cause water to be intermittently pulled below the wire for drainage and re-injected into the sheet to re-fluidize the fiber slurry on top of the wire and improve formation. The curved shape of the blade surface was substantially more efficient than straight angle surfaces of standard foils causing the water to follow the blade surface in a controllable manner.

This controlled drainage and fluidization prevents sheet sealing and improves formation, but as the name implies, it is still velocity dependent. To utilize VID forming technology over a wide speed range without the need to change blades, structures with blades that are movable in both vertical and angular planes were developed. Automating the VID forming technology structure, so it is controlled by the mill’s DCS as speed varies is critical to optimal performance but requires a commitment to preventative maintenance in a harsh environment.

Following VID forming technology was the development of the Deltaflo, iI-Table® and others adjustable fourdrinier technology around 2006. This technology consists of many foil blades and wear surfaces moved by numerous electric motors and produces a wire pulsation dependent on wire speed.

High-Resolution™ Forming System

Papermakers have realized the value of adjustable table elements in drainage and formation, but the most advanced equipment available since the turn of the century has been expensive, complicated, and maintenance intensive.

Kadant Solutions took a new approach in 2013 to control the formation zone of the table. Working with a mill producing linerboard at speeds ranging from 1,800 to 3,200 feet per minute, we evaluated the pros and cons of existing equipment and systems to develop a new solution utilizing a combination of proven components.

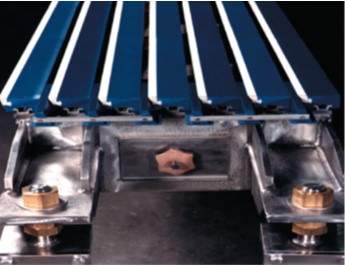

The result was the High-Resolution forming system. The High-Resolution forming system uses high capacity, multi-compartment, low vacuum augmented drainage structures following the forming board that employs stepfoil forming blades with extremely accurate vacuum control.

The multiple vacuum zones in the structures allow precisely graduated vacuum control for each grade produced eliminating sheet sealing, while the positive, variable pressure pulses created by the stepfoil forming blades improve sheet formation. The High-Resolution forming system has no moving parts near the machine. Sheet activity is vacuum dependent; not speed or blade shape dependent.

When lightweight grades are produced at high speed, the vacuum in the structures is reduced to extremely low levels (0 – 2” water) reducing the catenary deflection of the wire between blades. This reduces the energy imparted into the sheet. Drainage in this mode approximates low angle gravity foils. When basis weights are increased, the need for drainage and activity increases as well. By controlling increased vacuum levels in the compartments and the wire catenary, the resultant drainage and formation increases without sheet sealing.

Key components of the High-Resolution Forming System

The off-machine V-1000™ vacuum control valves are self-contained. Force balanced controllers that react instantly to small vacuum changes to maintain the precise (+/- 0.25 inches of water) vacuum levels needed. Operating in a user-friendly environment away from the fourdrinier wet end, the maintenance of these valves is simple, reliable, and safe with the machine running.

The off-machine V-1000™ vacuum control valves are self-contained. Force balanced controllers that react instantly to small vacuum changes to maintain the precise (+/- 0.25 inches of water) vacuum levels needed. Operating in a user-friendly environment away from the fourdrinier wet end, the maintenance of these valves is simple, reliable, and safe with the machine running.

The use of stepfoil forming blades is the second component of this system. These ceramic tipped blades have a secondary pressure pulse which is dependent on the gap between the wire and the step of the blade. As vacuum increases (heavier weights), the wire deflects closer to the blade and the pulse amplitude increases to improve activity, formation, and drainage. Further, with a larger wire catenary, inertia carries the water through the wire to be doctored off by the lead edge of the subsequent blade.

The use of stepfoil forming blades is the second component of this system. These ceramic tipped blades have a secondary pressure pulse which is dependent on the gap between the wire and the step of the blade. As vacuum increases (heavier weights), the wire deflects closer to the blade and the pulse amplitude increases to improve activity, formation, and drainage. Further, with a larger wire catenary, inertia carries the water through the wire to be doctored off by the lead edge of the subsequent blade.

The third component of the system is the high capacity, multi-compartment design of the structures located immediately following the forming board where the amount of water removed may be very large. To handle the water volume, the High-Resolution forming system uses structures with full width integral J-legs.

The third component of the system is the high capacity, multi-compartment design of the structures located immediately following the forming board where the amount of water removed may be very large. To handle the water volume, the High-Resolution forming system uses structures with full width integral J-legs.

There are no wet end moving parts for maximum reliability and personnel safety.

Results

The High-Resolution forming system has successfully been in operation since 2013 on a linerboard machine producing 31 lb. to 96 lb. (per thousand sq. ft.) board at speeds up to 3,200 feet per minute. Multiple world production records for a flat fourdrinier machine have been set–most recently a record 1,870 tons in 24 hours was achieved with 226-inch trim on 69 lb. liner. Better sheet activity control has improved formation allowing press load increases and substantial steam savings as well as higher calendar loading and sheet smoothness along with improved primary table cleanliness. This initial installation has been followed by additional packaging grade installations all with similar quality and production improvements.

iTable is a registered mark of IBS of America Corporation. Kadant Inc. and its subsidiaries are not affiliated with or sponsored by IBS.