Six Common Spray Nozzle Problems and Prevention

Spray nozzles are a precision engineered component that plug and wear over time during normal operation or cleaning. Plugged spray nozzles negatively affect process machine productivity and cost.

Here are six common problems associated with the operation of spray nozzles:

- Erosion or Wear

Erosion or wear of the spray nozzle is caused by continued high pressure liquid flowing through the spray nozzle orifice over time. This flow gradually removes metal and causes the orifice to enlarge. As a result, flow increases and pressure decreases, and the spray pattern becomes irregular. - Corrosion

Spray nozzle orifices and the nozzle body become corroded based on the type of liquid being sprayed and the nozzle environment. Proper material selection is critical when using a spray nozzle in a corrosive environment. For example, use of a titanium nozzle when bleach is being used. - Temperature

Certain process conditions require elevated liquid temperatures to enhance cleaning. This elevated temperature will soften the metal and cause accelerated nozzle orifice wear. - Caking or Filler Build-up

Build-up of fillers and minerals from dissolved material, such as iron can adversely affect the spray nozzle orifice. The nozzle will have a poor spray pattern, increased pressure and reduced flow. - Accidental Mechanical Damage

This is the most widespread problem causing poor spray nozzle performance leading to nozzle replacement. It leads to poor spray patterns, increased pressure and reduced flow. - Nozzle Orifice Clogging

Unwanted solid particles found in the water stream that are larger than the spray nozzle orifice will block the orifice. This causes poor spray patterns, increased pressure and reduced flow.

Preventative Maintenance

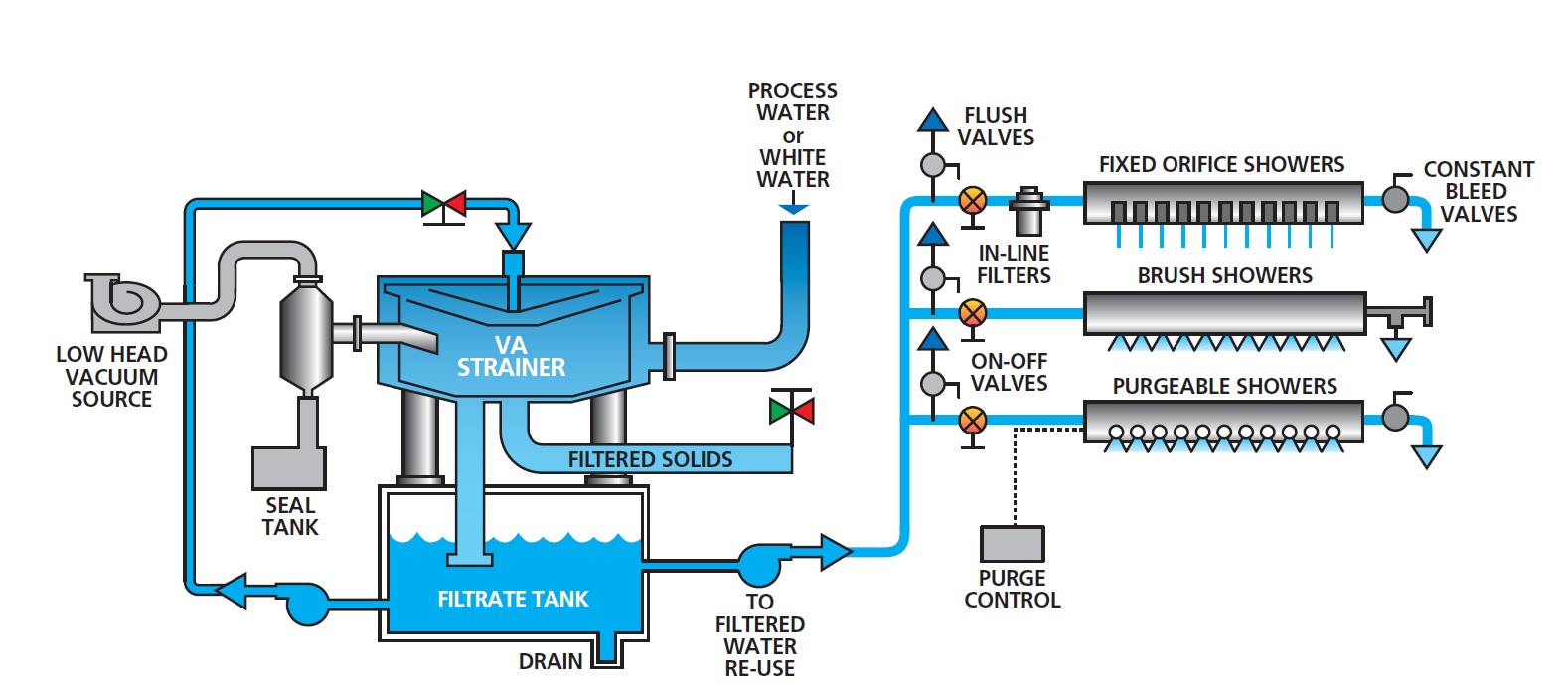

Proper filtration is key to protecting the spray nozzle orifice. Filtration to the inlet side of the pump and at the shower inlet are the best positions for a filter. Various filter types can be used including gravity strainers and pressure filters. The following schematic shows a common filter arrangement.

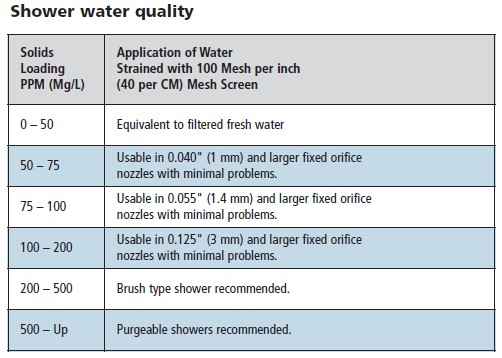

Water quality and usage is another factor in spray nozzle health. A proper analysis of accept water when selecting shower hardware is important. With cleaner water, fixed orifice spray nozzles have less blockage problems.

As the solids loading increases, it is necessary to select a shower with nozzles that can be cleaned while running. Brush or purgeable showers provide on-the-run nozzle cleaning features. Spray nozzles with internal extensions and screens also can help with plugging issues.

In addition to filtration and water quality it’s important to choose the proper orifice size for the application. The table to the right shows the recommended solids loading as a function nozzle orifice size.

Let's Connect

Connect with Kadant Solutions Division on LinkedIn to learn more about our employees, products, and services.