Case Study: Corrugator Increases Run Rate 20% on Double Wall Corrugated Board

Challenge

A corrugator in the Denver area was unable to run double wall corrugated board over 550 fpm. Double wall was 15 to 20% of their output and the speed bottle-neck was limiting their production window for all board types. At speeds over 550 fpm, the starch adhesive glue lines on the double wall flutes were not having sufficient time to set, bond, and cure (white-lining) as they went through the double backer. The corrugator had to limit speeds or risk web separation.

Solution

Solution

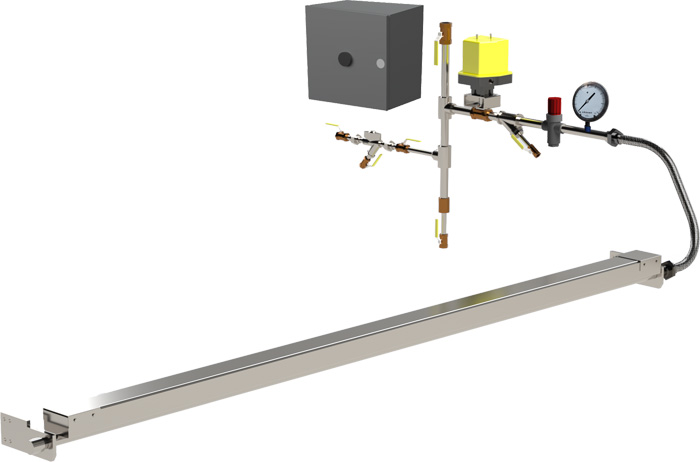

The bars were premeasured by Kadant Johnson and installed on the existing double facer frames using simple brackets. The existing steam header was used to supply steam through the mechanical steam controls provided by Kadant Johnson. The control box activates the mechanical controls based on machine speed.

Results

The corrugator was able to increase run speeds on double wall board 20% in virtually all cases. The added heat decreased the time to set, bond, and cure the adhesive to the liner and medium. The corrugator was not only able to run faster on double wall board but also open up production capacity for all board.