Expansion Joint Customization

Standard configurations of expansion joints fulfill many needs in the piping and ducting world. Systems are designed to accommodate these standard sizes. Over time, factors such as settling, warpage, and updates can create a need for a custom expansion joint. Misalignments, reducers, and differences in flange drillings can create situations that many expansion joint manufacturers may try to avoid. Kadant Unaflex thrives in this situation. The Kadant Unaflex team has created custom configurations to meet the needs of its customers for over 40 years and have become known as the problem solvers in the expansion joint industry.

Standard configurations of expansion joints fulfill many needs in the piping and ducting world. Systems are designed to accommodate these standard sizes. Over time, factors such as settling, warpage, and updates can create a need for a custom expansion joint. Misalignments, reducers, and differences in flange drillings can create situations that many expansion joint manufacturers may try to avoid. Kadant Unaflex thrives in this situation. The Kadant Unaflex team has created custom configurations to meet the needs of its customers for over 40 years and have become known as the problem solvers in the expansion joint industry.

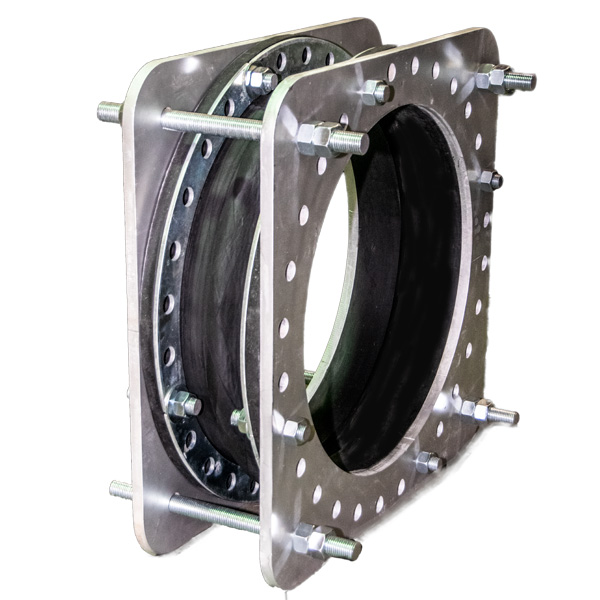

Misalignments are a primary reason for customized configurations. Misalignments are often the result of foundation settling in older facilities causing unnecessary stress on a standard expansion joint. A standard, straight-line configuration could be positioned to create the proper connection between the pipe segments. This forcing of the joint never allows the joint to return to its resting position. Kadant Unaflex can create the offset needed that allows the joint to properly rest when thermal and mechanical forces are not acting upon the system.

Customization does always have to be the result of alignment issues. In some cases, a section of piping may have different internal diameters or different flange drilling patterns all of these can be achieved with custom joints.

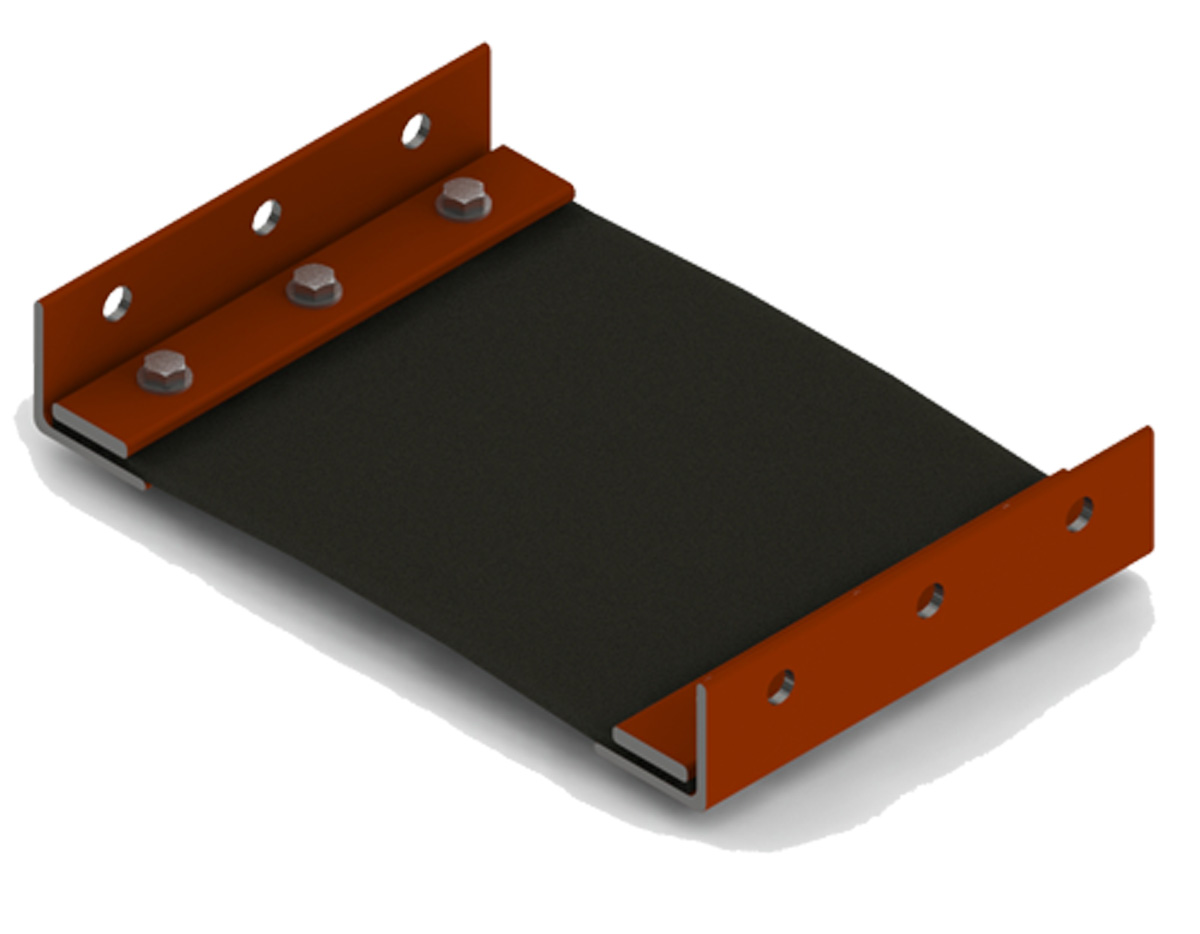

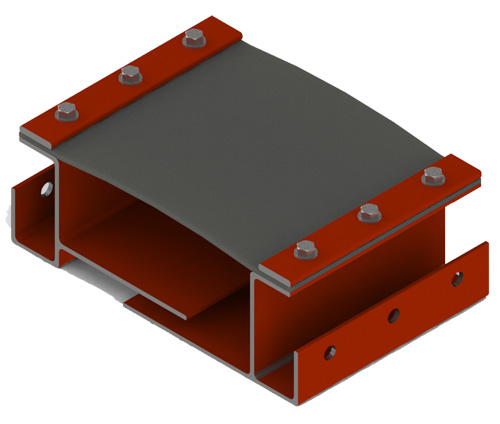

Customization of joints is standard in the fabric expansion joint line. The Thermaflex line of products is specifically designed for this type of application. Fabric expansion joints typically consist of a metal frame that attaches to the mating flanges while also connects the belt across the void. The frames may include a stand-off such a “J” frame or without as in a “A” frame design. Fabric expansion joints are primarily for use in high temperature, low pressure applications such as ducting and exhaust.