The Advantages of a Secure-Flex™ Rubber Expansion Joint

One of the most challenging aspects of expansion joints is getting the right joint for your application. Often this is exasperated by settlings in support foundation causing misalignment of the expansion joint. Linear misalignment can be addressed by built-in offsets to the construction of the expansion joint. Drilling misalignments may be harder to detect until installation is complete.

One of the most challenging aspects of expansion joints is getting the right joint for your application. Often this is exasperated by settlings in support foundation causing misalignment of the expansion joint. Linear misalignment can be addressed by built-in offsets to the construction of the expansion joint. Drilling misalignments may be harder to detect until installation is complete.

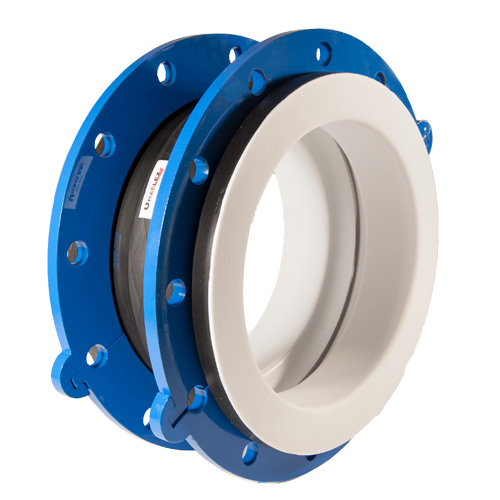

A recommendation from Kadant Unaflex to prevent this is the Style 7000 Secure-Flex rubber expansion joint series. This series of expansion joints combines the performance of a Super-Flex™ Style 1000 with a wide arch design allowing for maximum movement with minimal face to face dimensions. One defining feature of the Secure-Flex expansion joint is the interlocking Van Stone or floating flange design. Unlike the Style 1000, which has a standard duck and rubber flange that is integral to the body of the expansion joint, the Style 7000 Secure-Flex version has no rubber flange but comes with steel flanges that are separate from the body of the expansion joint making installation easier. The floating flange design makes any drilling misalignment an easy adjustment as well. Along with the advantages of the floating steel flange construction, the Style 7000 Secure-Flex expansion joint uses a Kevlar reinforcement layer giving it greater pressure capacity than a standard Style 1000 model. Since its introduction, the Style 7000 model has become one of the most popular expansion joint configurations in the Kadant Unaflex catalog.

Whether you are designing a new pipe system or replacing the expansion joints in an existing system, Kadant Unaflex is your singular source for expansion joint solutions. Our extensive line of expansion joint products can all be customized precisely to meet your needs.

Questions?

Contact our knowledgeable sales staff to learn how Kadant Unaflex can help you resolve your piping and ducting concerns.