The Never-Ending Battle of Stickies

Recycled fibers are critical for sustainable paper and board production, but they are often contaminated with stickies and waxes from adhesives. Low adhesive stickiness is necessary to ensure high-quality tissue, packaging, and graphic paper products. Stickies can cause issues such as deposits, breaks, and clogging, which reduce process efficiency and final product quality.

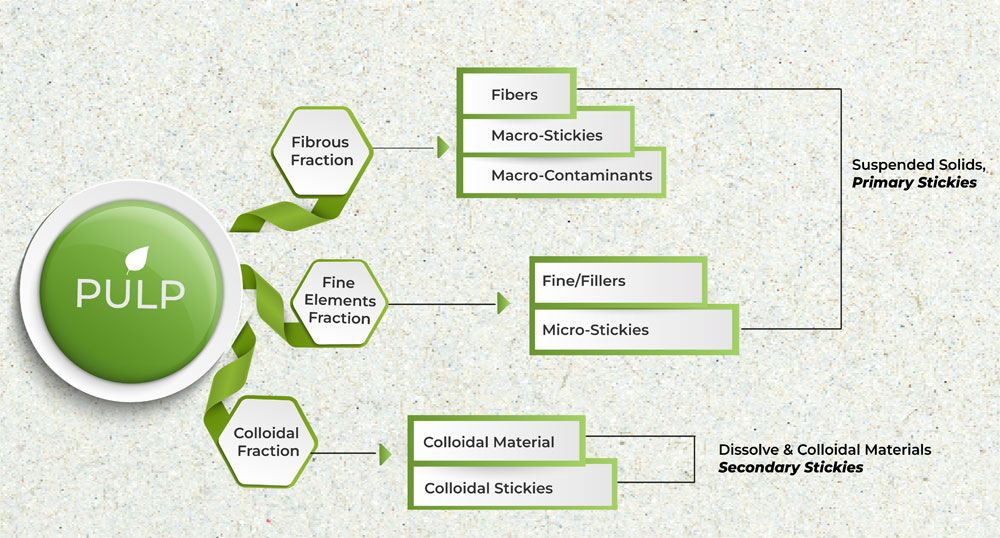

Effective measures to remove stickies are necessary to improve production efficiency, reduce costs, and enhance product quality. Sustainable methods for managing and controlling stickies in recycled fibers are essential for a successful manufacturing process. We classify the different types of sticky contaminants into various families, as shown in the chart below.

Stickies are a significant challenge in paper production, but proper management can result in optimal product quality and cost savings.

- Have you assessed the impact of stickies on your operational costs? Have you ever wondered why the stickies problem persists in mills, despite implementing measures such as slot screening, dispersion, and chemistry?

- Have you experienced days without sticky problems and suddenly encountered a stickiness nightmare without changing your raw materials or operational settings? Have you wondered why this was happening?

- Have you attempted to find a solution and failed to find one that solves your sticky problems?

If you relate to any of the questions above and seek reliable solutions and support services,