Beyond Steam: An Interview with Jordi Gifre, New Sales Director of Kadant Johnson Systems International S.r.l

In the paper industry, a transformation is underway, led by Kadant Johnson Systems International's innovative approaches and cutting-edge solutions. The recent promotion of Jordi Gifre as Sales Director, overseeing the steam and condensate division for the paper industries in Europe, marks a new chapter in this journey. With more than a decade of commitment to the company, Jordi brings expertise and a visionary perspective to Kadant’s mission: optimizing paper production processes using technology, know-how, and expertise to deliver an ROI in energy, tonnage, environmental, and quality performance.

In the paper industry, a transformation is underway, led by Kadant Johnson Systems International's innovative approaches and cutting-edge solutions. The recent promotion of Jordi Gifre as Sales Director, overseeing the steam and condensate division for the paper industries in Europe, marks a new chapter in this journey. With more than a decade of commitment to the company, Jordi brings expertise and a visionary perspective to Kadant’s mission: optimizing paper production processes using technology, know-how, and expertise to deliver an ROI in energy, tonnage, environmental, and quality performance.

Kadant Johnson Systems International stands as an example of innovation in the paper mill sector, known for its extensive portfolio of solutions that extends from rotary joints and syphons to doctoring, cleaning, and filtration systems and, of course, steam and condensate systems. All these offerings are solutions engineered to elevate the operational efficiency and environmental sustainability of paper mills.

How does Kadant face the challenge of energy efficiency optimization in paper mills?

How does Kadant face the challenge of energy efficiency optimization in paper mills?

Optimization is at the heart of our solutions, starting with our extensive Energy Surveys. This service is crucial to solving the inefficiencies associated with the drying section of paper mills, where steam is essential for drying paper, but can lead to many problems if the steam and condensate system is unbalanced or improperly regulated. Such issues can range from flooded dryers and vented uncondensed steam, to the unintended production of hot water and high-temperature condensate return, all of which contribute to quality non-conformity, reduced machine runnability and efficiency, and elevated production costs. Leveraging years of expertise, Kadant’s approach goes beyond the evaluation of the steam and condensate system; it also identifies additional problems affecting paper production, such as stickies, dusting, or wrinkling, by recommending alternative control methods for the machinery.

During an Energy Survey, our engineers perform a detailed evaluation of the drying section, examining:

- System layout

- Component functionality

- Component sizing

in order to pinpoint real opportunities for energy savings and enhanced drying capacity. This detailed evaluation includes:

- Physical inspection of the steam system

- Data collection

- Careful analysis of the process's heat transfer

- Steam consumption efficiency

How does Kadant improve energy efficiency optimization in paper mills?

Based on these results, Kadant prepares a proposal for an optimized system targeting solutions that typically offer an ROI (return on investment) within two years. Kadant presents these findings as a neutral party, ensuring that the results are quantifiable and actionable. Examples of products that are part of a system that delivers significant energy savings and improved operational efficiency in paper mills are:

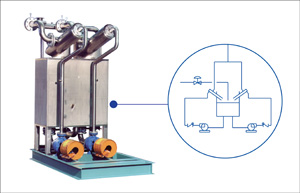

Separator tanks that are designed to efficiently separate flash steam and condensate for stable and trouble-free operation.

Separator tanks that are designed to efficiently separate flash steam and condensate for stable and trouble-free operation.

Vortec™ vacuum generator that eliminates the need for traditional, maintenance intensive vacuum pumps.

Vortec™ vacuum generator that eliminates the need for traditional, maintenance intensive vacuum pumps.

Thermocompressors that use high-pressure motive steam to boost the pressure of dryer blow-through, increasing flexibility and allowing the efficient reuse of low-pressure steam.

Thermocompressors that use high-pressure motive steam to boost the pressure of dryer blow-through, increasing flexibility and allowing the efficient reuse of low-pressure steam.

What makes Kadant's paper solutions so special?

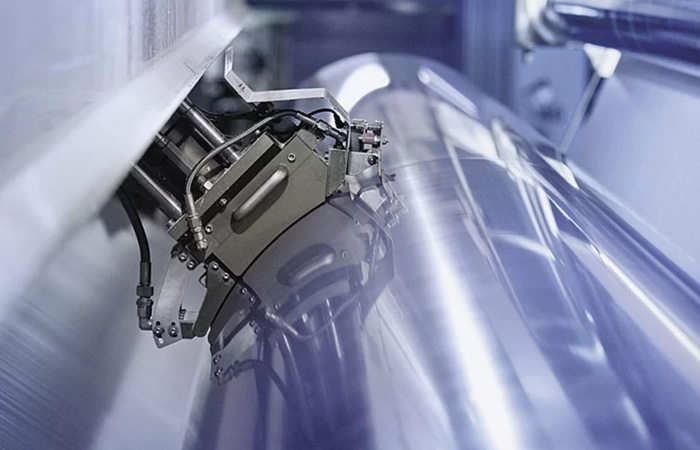

Our customers benefit significantly in terms of ROI, efficiency, and energy savings. For example, our advanced PT2X™ steam joints ensure efficient and consistent heat transfer, reducing operating and maintenance costs. In addition, our M-clean™ system technology drastically reduces water consumption and costs associated with fabric cleaning. Each solution is customized to meet specific customer requirements, ensuring tangible improvements in productivity and sustainability.

PT2X™ steam joint PT2X™ steam joint |

M-clean™ System M-clean™ System |

What is the role of Kadant's R&D Center in developing solutions for paper mills?

Our R&D Center is crucial in keeping Kadant a leader in innovation. Here, papermakers can test their latest ideas under simulated operating conditions, exploring new steam and condensate options for their machines. We offer a real-time view inside the dryer cylinders, allowing them to select and demonstrate the optimal combination of rotary joints, syphons, and Turbulator® Tube bars™ to meet specific requirements. This commitment to R&D opens the door to advanced drying solutions, energy savings and efficiency improvements.

What are your goals as the new Sales Director for Steam & Condensate in Europe?

My main goal is to enhance relationships with our current and future customers by demonstrating how our solutions can lead to significant improvements in operational efficiency and environmental sustainability.

I want our customers to see Kadant not just as a supplier, but as a true strategic partner that can support them in solving their daily challenges. This means working closely with them to fully understand their specific needs and provide customized solutions that optimize their production, reduce operating costs, and improve their environmental footprint.

Another key objective is to increase awareness of the innovations we are bringing to the market. This includes educating our customers about the ROI of our advanced solutions, which offer advantages in terms of energy efficiency and operational reliability.