Fluid Handling Solutions for the Chemical & Pharmaceutical Industry

In more recent years, operational efficiency and environmental sustainability have become higher priorities within the chemical industry,

Advanced fluid handling technologies, such as rotary joints and unions, are critical for optimizing chemical and pharmaceutical manufacturing processes. Kadant Johnson's fluid handling solutions are integral in applications involving mixing, blending, heating, and cooling.

Innovative products, including expansion joints, rotary unions, sealing devices, steam and condensate systems, and water heating solutions, enhance process efficiency, lower energy costs, and promote sustainable operations.

Within this industry, stringent cleanliness and sterilization standards are mandatory, meaning these products must ensure top-of-the-line performance. Kadant Johnson's innovation and research allow highly specialized and reliable solutions tailored to meet the unique demands of advanced industries. These solutions support companies in achieving optimal production efficiency and maintaining compliance with rigorous safety and quality regulations, such as those set by ATEX or FDA.

ROTARY JOINTS / ROTARY UNIONS

Kadant's rotary joint and rotary union technologies are essential for the efficient and reliable transfer of various media, including steam, water, and oil, between stationary and rotating equipment. This technology is fundamental in enhancing the efficiency and reliability of production processes.

Rotary joint sealing technology ensures durable, leak-free performance, tailored to process speed, pressure, temperature, and media type. Our standard rotary joints, suitable for chemical and pharmaceutical applications, are designed to transfer one or two media simultaneously, and can have ATEX and FDA approved design. For more complex requirements, the multi-pass rotary unions can handle up to twelve media types, providing omnidirectional flow.

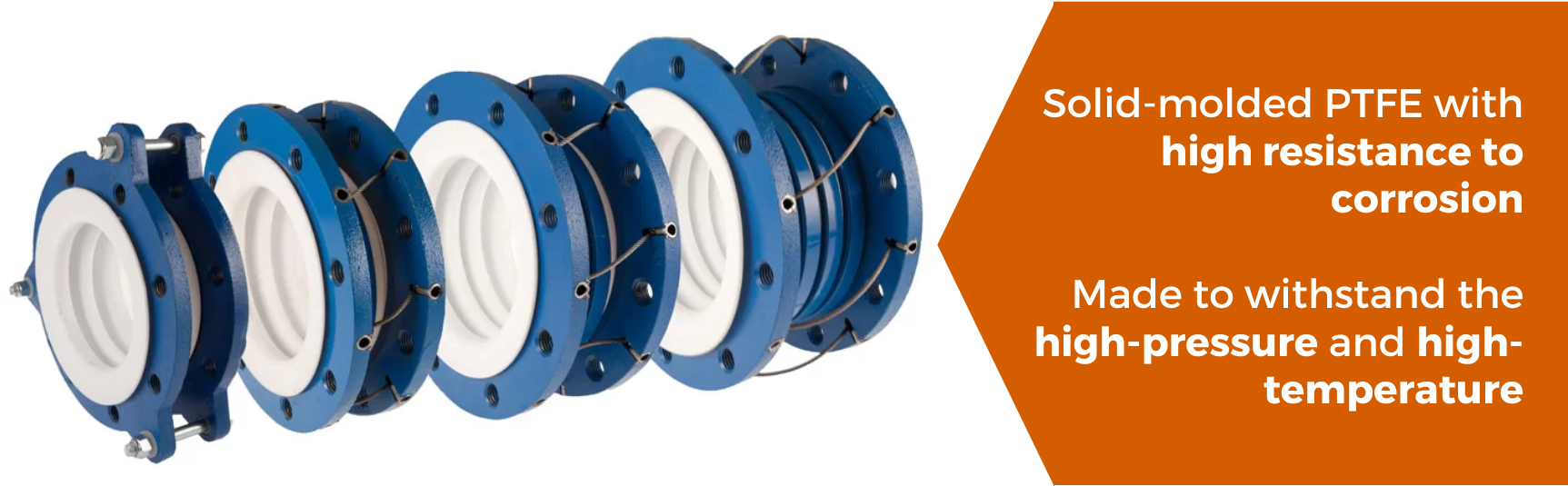

EXPANSION JOINTS

Kadant's PTFE expansion joints are renowned for its corrosion resistance and capability to withstand high pressure and temperature, making them ideal for compact and demanding applications.

Solid-molded PTFE expansion joints offer exceptional corrosion resistance and are designed to operate under high pressure and temperature in a space-saving configuration. Available in standard sizes from 1” to 12” with two, three, or five convolutions, these expansion joints can be manufactured up to 48” in size. They operate efficiently across a temperature range from -300°F to 400°F and can handle pressures from full vacuum to 160 psi, depending on the type and number of convolutions.

CONDENSATE PUMPS AND THERMOCOMPRESSORS

Kadant’s pressure powered pumps use steam or air pressure to move condensate, allowing processes to operate at low pressures with minimal moving parts, avoiding the energy loss associated with cooling condensate for electric pumps. The Liqui-Mover® series includes float-operated and float-free models, suitable for various capacities and applications, particularly where electricity is impractical or hazardous.

Thermocompressors boost low-pressure steam to higher pressures for reuse, maximizing energy efficiency by retaining the energy in low-pressure steam while increasing its pressure through high-pressure steam mixing. With components like a nozzle, mixing section, and diffuser, thermocompressors are simple yet highly efficient. They are used in applications such as recycling waste steam and adjusting superheated steam to suitable pressure and temperature for downstream processes.

Explore these solutions and start your plant’s journey towards greater efficiency and enhanced environmental responsibility.