What are the Advantages of Externally Pressured Metal Bellows Expansion Joints?

Many of these types of expansion joints come with a drain that allow excess to be removed from the system. Pressurized steam systems are a common place you will find these type of expansion joints. Self-draining convolutions of the bellows element make it impossible for media to collect in the convolutions.

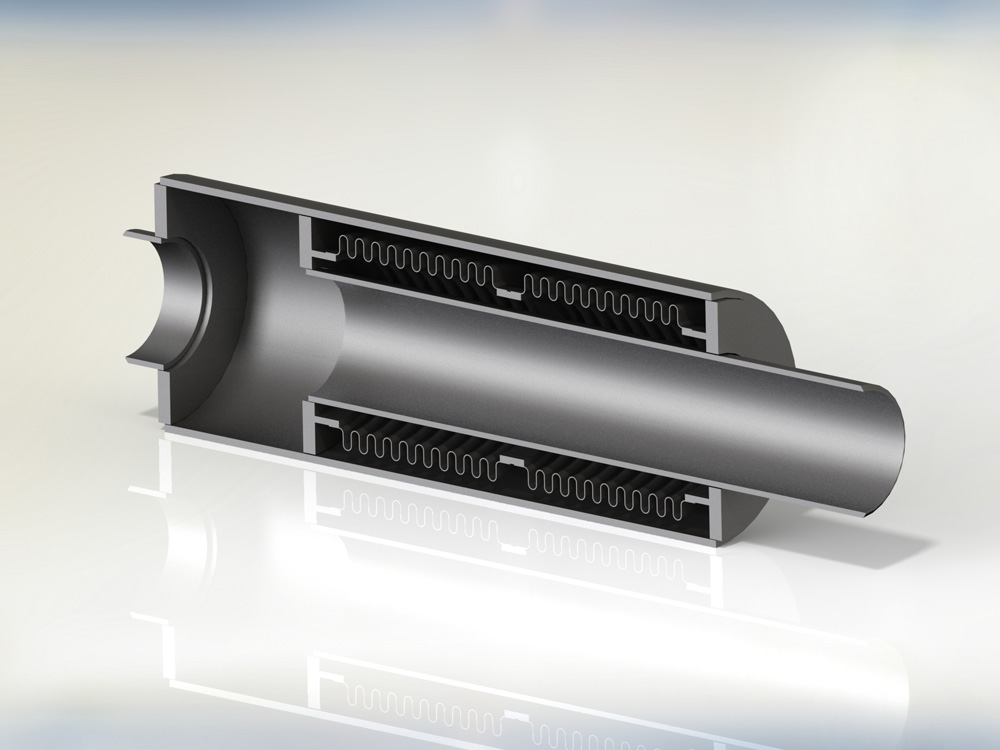

Some inherent features of this design include guide rings, full thickness cover, insensitivity to flow direction, and these joints meet EJMA guidelines for safety. The internal guide rings reduce the need for guides and anchors compared to internally pressurized bellows. These expansion joints do not require liners and are easy to insulate. The external casing protects the bellows element making installing easier and less time consuming with no critical surfaces exposed.

Expansion Joint Customization

All of our bellows expansion joints can be custom made for your application.