The Liqui-Mover® Float Operated Pump’s Reputation for Durability Starts with Spring Design

Spring failures can occur in some manufacturer’s float level control pressure powered pumps due to harsh environments and repeated cycling. The three main causes of spring failure are chloride stress cracking, contaminants, and work hardening.

Spring failures can occur in some manufacturer’s float level control pressure powered pumps due to harsh environments and repeated cycling. The three main causes of spring failure are chloride stress cracking, contaminants, and work hardening.

Chloride Stress Cracking

Chloride stress cracking can be caused by spring contact with condensate. Most maintenance departments have little control over boiler chemistry so the spring must be designed to withstand a range of chemistries. Exotic materials, like Inconel® alloys, have been used to increase the life of springs, but the material doesn’t reduce the stress created during compression. A low-stress open-coil design is the best answer. Chloride stress cracking is caused by the chlorides in the condensate attacking high stress points in the spring material. If the stress in the spring is maintained at a low level, chlorides in the condensate cannot attack the material. This reduced stress also increases the cycle life of the spring.

Contaminants

When springs contact condensate, dirt carried down the pipes to the pump via the condensate can get in between the coils of the springs. When the spring draws apart and snaps back, the dirt can cause nicks in the spring metal. The nicks cause stress concentrations and can cause the spring to break.

Work Hardening

A third cause of failures is poor spring design that allows the coils to contact or hammer against each other when the pump cycles. In this case, even if dirt isn’t present, the contact creates work hardening. Over time, this can cause breakage as the coils lose elasticity and spring stress climbs.

A Better Spring Design

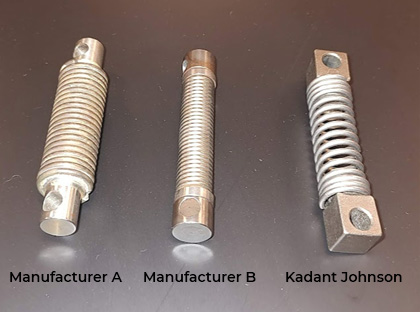

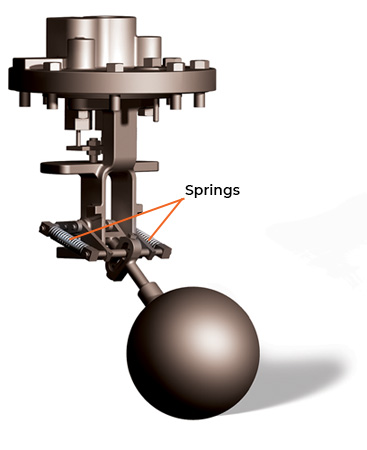

The design of the Kadant Johnson float operated mechanism uses an open coil spring design and a proprietary spring material. The widely spaced coils prevent contaminants from creating nicks in the spring or work hardening the spring because the coils are widely gaped and do not come in close contact. This also helps reduce spring stress and the effects of chloride stress cracking. A proprietary spring material provides further robustness to corrosion and stress.

Kadant Johnson’s spring design is standard on all Liqui-Mover® float level control pressure powered pumps. It is also a part of the float operated replacement level control kits for upgrading and retrofitting most major brand pressure powered pumps.

|

Kadant Mechanism |

Spring Comparison |

|

|

Note: Inconel is a registered trademark of Special Metals Corporation