What Is a Thermocompressor?

A thermocompressor is a jet powered device that saves energy by recycling low-pressure waste steam into higher pressure steam for use in industrial processes.

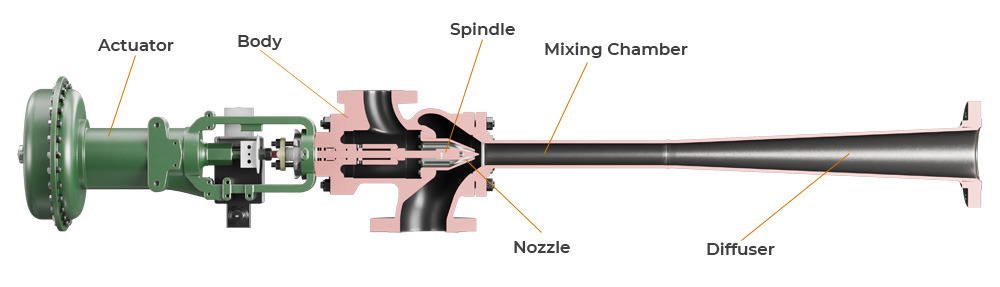

Parts of a Thermocompressor

A thermocompressor has three main sections. A precision actuator that precisely controls the relative location of the spindle and nozzle, a body and mixing chamber that house the spindle and nozzle, and a diffuser that expands with length.

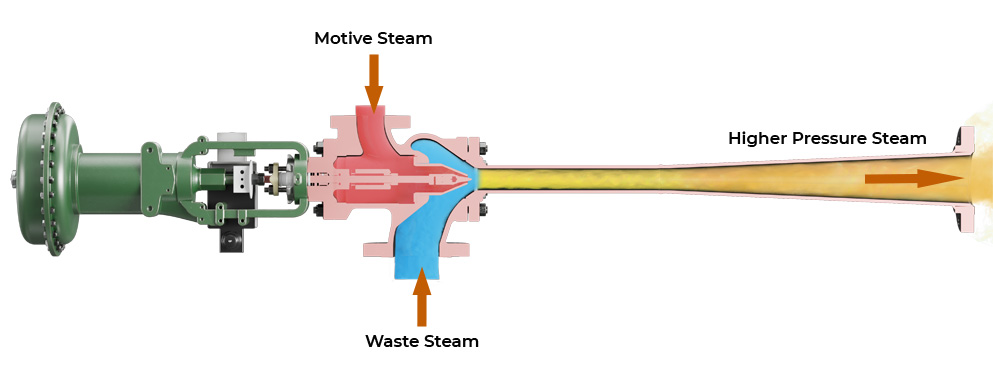

Boosting Steam Pressure

To capture 100% of the energy in low-pressure waste (suction) steam, high-pressure motive steam enters the thermocompressor body and accelerates out the nozzle, entraining the waste steam in the mixing chamber. A precision actuator regulates the flow of motive steam. This minimizes the amount of motive steam used across operating conditions. As the combined steam exits the diffuser, it expands, the velocity of the steam slows, and the pressure increases. The resulting steam is at a higher pressure than the waste steam and is ready for use in industrial processes.

Engineered for the Application

Kadant Johnson engineers each thermocompressor for its application to maximize efficiency. To learn more, see how Kadant Johnson thermocompressors work in this short animation.